When you browse our extensive range of woven wire mesh, you may come across the term ’twill’.

This less common type of metal mesh is used in a variety of applications, from construction projects to making furniture.

This blog will elucidate you on all aspects of this mesh. Subjects include a definition, how it is made, how it compares to other weave types and more.

Let’s get into it….

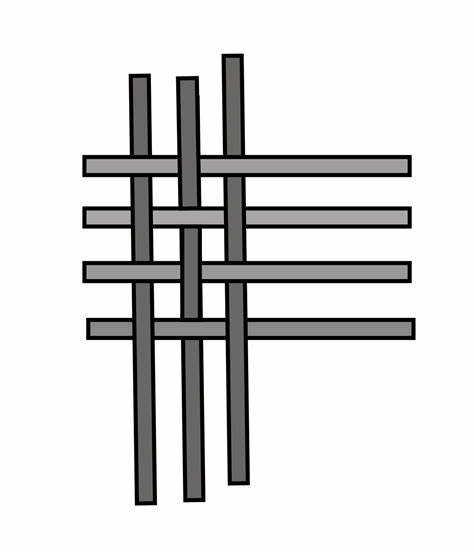

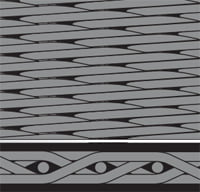

Stainless steel twill weave woven wire mesh is a type of metal mesh that consists of fine wires woven together in a non standard pattern. Twill.

Throughout the fabric, weft wires alternate above and below successive pairs of warp wires. It is possible to use a heavier wire diameter in this weave than in a plain weave wire mesh with the same mesh count.

Twill is ideal for applications where rigidity and durability are needed, such as in construction projects or furniture making.

Twill weave woven wire mesh is made using a specialized weaving method that differs from normal weaving methods.

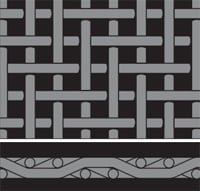

In twill weave, the wires are woven over and under each other in a staggered pattern, creating a diagonal or herringbone effect. This is unlike the normal weaving methods, where the wires are woven in a more traditional over-and-under pattern (plain weave).

To create twill weave woven wire mesh, the wires are first tensioned on a loom. The weft wire is then passed over and under the warp wires, moving across the loom at an angle. This angle creates the distinctive diagonal pattern of twill weave. The weft wire is then passed over one or more warp wires, creating a repeat pattern that produces the desired mesh size and shape.

You may wonder which is preferable between twill and plain weave.

Here are some differences between the two:

Pattern: Twill weave and plain weave differ in their weaving patterns. Twill weave has a diagonal pattern, where each wire passes over and under two or more wires in a staggered fashion. Plain weave, on the other hand, has a simple over-and-under pattern, where each wire passes over and under one other wire. Both have their merits. For fine mesh sizes you would not be able to tell the difference without magnification.

Strength: Twill weave typically produces a stronger and more durable mesh than plain weave. This is due to the diagonal pattern, which distributes stress more evenly across the mesh and prevents individual wires from bearing too much weight.

Appearance: Twill weave produces a distinct diagonal pattern that gives the mesh a unique appearance, while plain weave produces a more uniform pattern with less texture. This is only evident on the larger weave sizes.

Mesh size: We tend to stock twill weave as fine mesh more often than anything else. This is because twill is very strong even as fine wire mesh. This is sometimes preferable for filtration if high pressure is used.

Application: Twill weave is often used in heavy-duty applications where strength and durability are essential, such as in mining, construction, and industrial settings. Plain weave is typically used in less demanding applications, such as in filtration or sieving. Plain weave is far more common, and easy to produce. Consequently it is usually lower in cost than twill.

No. Twill weave is a strong weave for sure, but there are other weave types that can be stronger depending on the specific application and requirements. Here are some examples:

Dutch weave: Dutch weave is a type of weave where the weft wires are thicker than the warp wires. This creates a tighter mesh and allows for greater filtration capacity.

Dutch weave can be stronger than twill weave due to its thicker wires and tighter mesh.

Reverse Dutch weave: Reverse Dutch weave is similar to Dutch weave, but with the positions of the warp and weft wires reversed.

In reverse Dutch weave, the warp wires are thicker than the weft wires. This creates a stronger mesh that is ideal for heavy-duty applications.

Twilled Dutch weave: Twilled Dutch weave is a combination of twill and Dutch weave, where the weft wires are woven in a twill pattern and the warp wires are woven in a Dutch pattern. The resulting mesh is strong and durable mesh that is ideal for applications that require both strength and fine filtration.

The most common use for a twill weave is as the mesh filter in the bottom of cafetières. Our group were involved in supplying mesh for the first ever model.

Twill is also commonly used in the construction industry for reinforcement purposes, as well as for making window screens, railings, fencing panels, and more. These tend to be heavy duty options.

It’s also used extensively in the manufacturing industry because it can be used to make filtration systems for liquids or air, as well as sieves for separating particles from liquids or gases. Aside from cafetières this is the most common type of project that we supply twill weave for.

As you can tell from the detail in this article, twill wire mesh is an incredibly versatile material which has many uses across various industries.

From construction projects to furniture making, this type of metal mesh offers superior strength and flexibility that makes it ideal for all sorts of applications.

If you are interested in a tough mesh spec for filtration then this may be the solution that you’ve been looking for.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions