Expanded metal, a transformative material in the world of construction and design, offers an unparalleled blend of versatility and functionality.

This article will focus on 10 x 8mm aluminium expanded metal. By focusing on one specification we can better explain the pros and cons of choosing this mesh type over wire mesh or perforated metal.

Due to its distinctive mesh structure and remarkable strength-to-weight ratio, this material outperforms traditional metal forms. Its manufacturing process, key characteristics, and dimensions and material composition will be examined along with their impact on its performance and suitability.

By dissecting its properties, applications, and benefits, we will demonstrate why this material is an excellent choice for those seeking a combination of strength, flexibility, and aesthetic appeal in their projects.

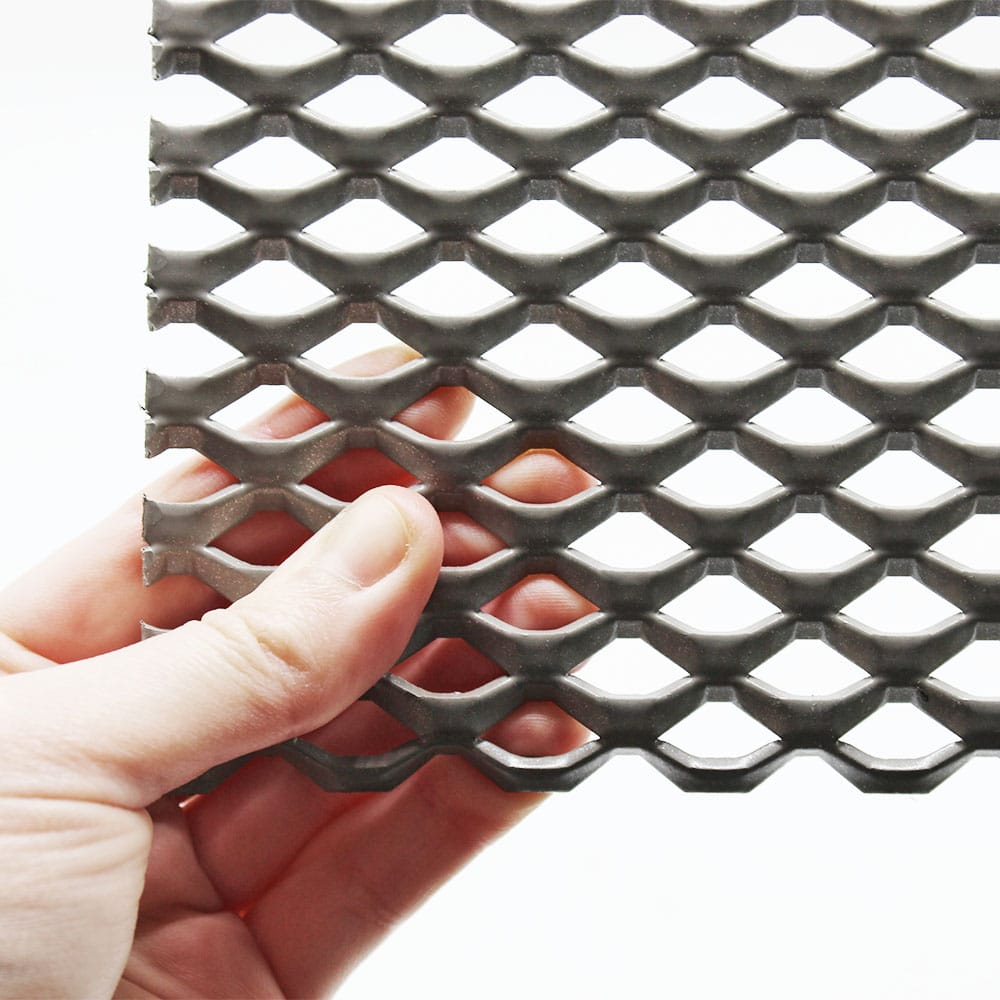

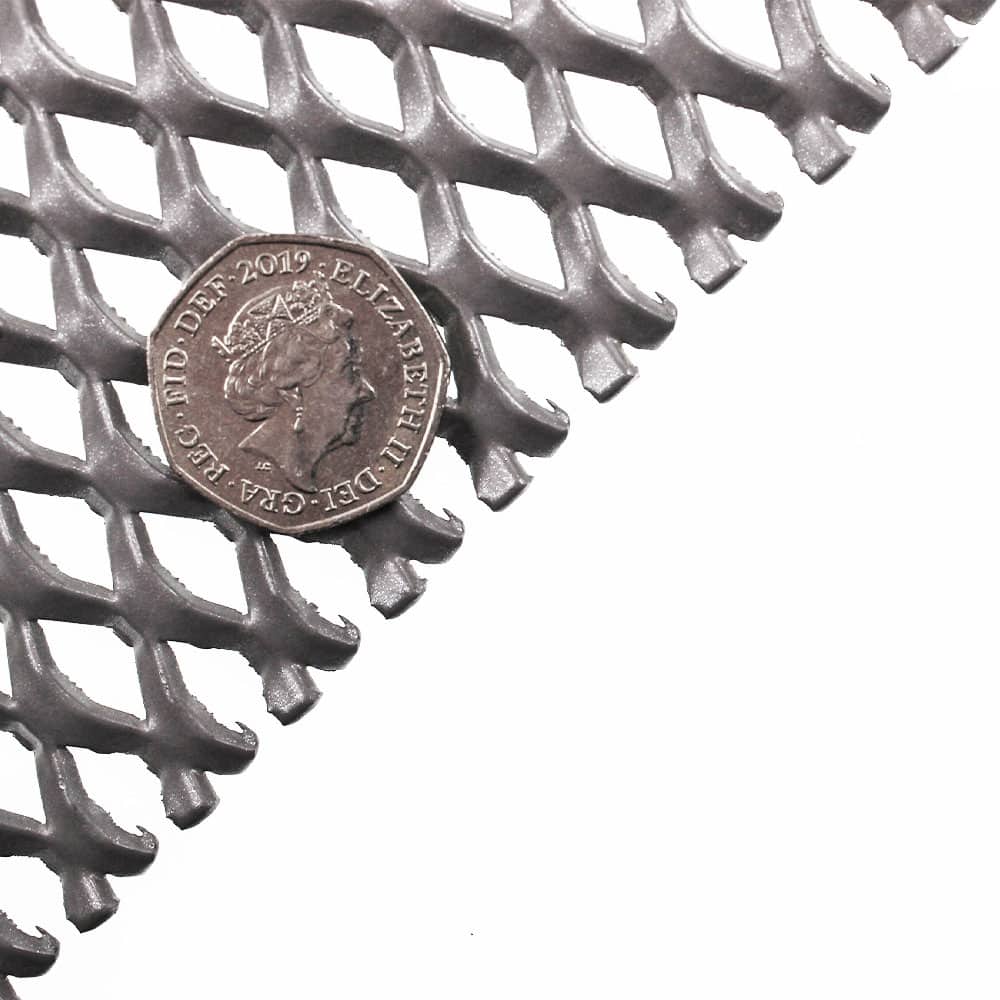

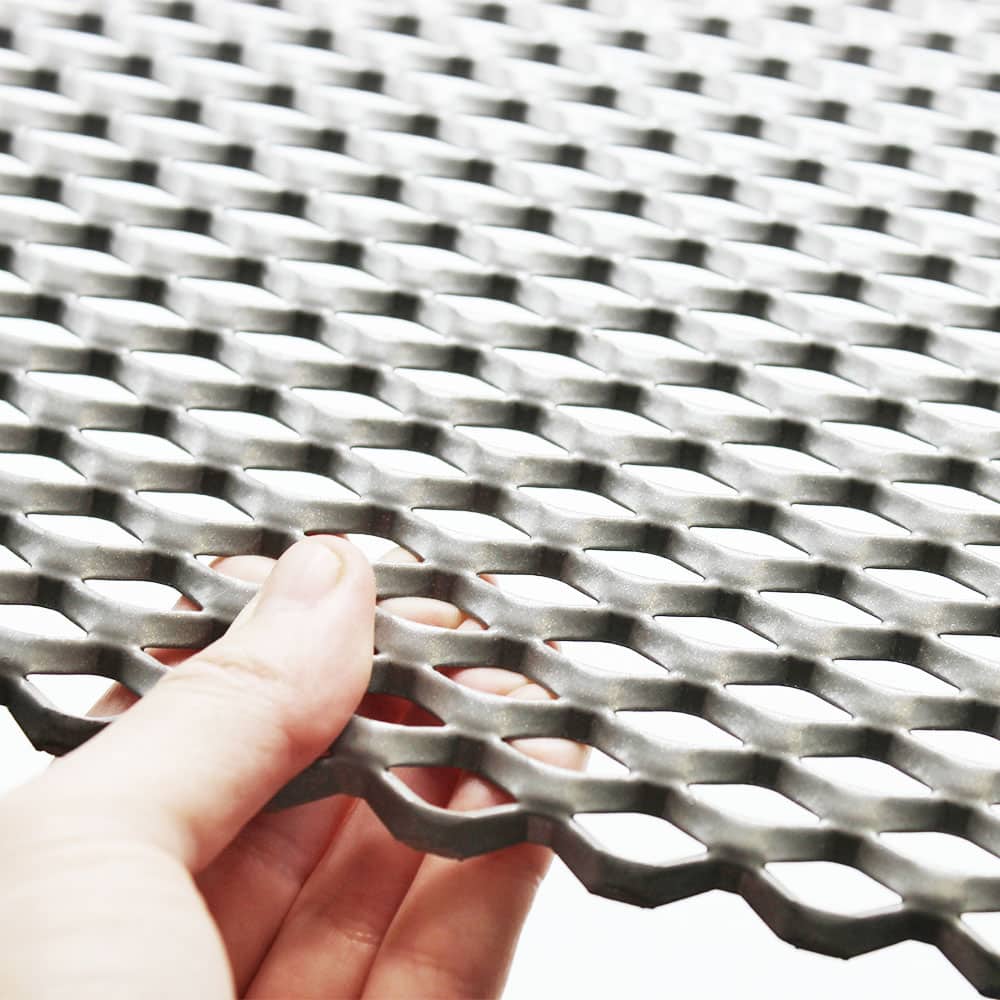

Expansion metal is made by cutting and stretching a solid metal sheet to create a mesh-like pattern. The single-piece material has no joints or welds, so it’s strong and rigid. Aluminum expanded metal 10 x 8mm goes through the same process, resulting in diamond-shaped openings measuring 10mm long and 8mm wide.

The open mesh structure of this type of expanded metal makes it stand out from other metal products. Mesh dimensions, especially the 10 x 8mm size, determine the material’s strength, flexibility, and transparency. Aluminum is the base material, which further enhances these characteristics, making it lightweight but strong.

With its unique structure, it’s perfect for everything from architectural facades to protective barriers.

The 10 x 8mm aluminium expanded metal is renowned for its exceptional strength and durability, attributes that are essential in many industrial and architectural applications. Despite its lightweight nature, aluminium as a base metal provides considerable resilience and robustness. This strength is a result of the expanded metal manufacturing process, which enhances the metal’s natural properties.

When compared to other materials like solid aluminium sheets or other metal meshes, the 10 x 8mm aluminium expanded metal excels in its weight-to-strength ratio. This means that while being lighter, it does not compromise on strength, making it an ideal choice for applications where durability is crucial but weight is a concern. For instance, in architectural applications like facade panels or protective screens, this expanded metal offers the necessary durability without adding excessive weight to the structure.

This balance of strength and lightness opens up a range of applications where traditional materials might not be suitable. From protective barriers in industrial settings to decorative elements in contemporary architecture, the 10 x 8mm aluminium expanded metal provides a durable solution without the burden of heaviness.

The lightweight nature of the 10 x 8mm aluminium expanded metal is one of its biggest advantages. The low density of aluminium makes this expanded metal easy to handle and install. Heavy materials can pose logistical challenges or increase installation costs.

The lightweight nature of this expanded metal makes it easy to transport, handle, and install, often without the need for heavy machinery. This ease of handling is not only a time-saver but also translates into cost savings in terms of transportation and labour. This material can cut down on labour costs and timelines in construction projects that require quick and efficient installation.

Also, aluminium’s malleability makes it easy to cut, shape, and fit into various designs and structures. With its adaptability, it’s great for custom applications, where it can be customised to meet specific design requirements without spending a lot of money on processing or modification.

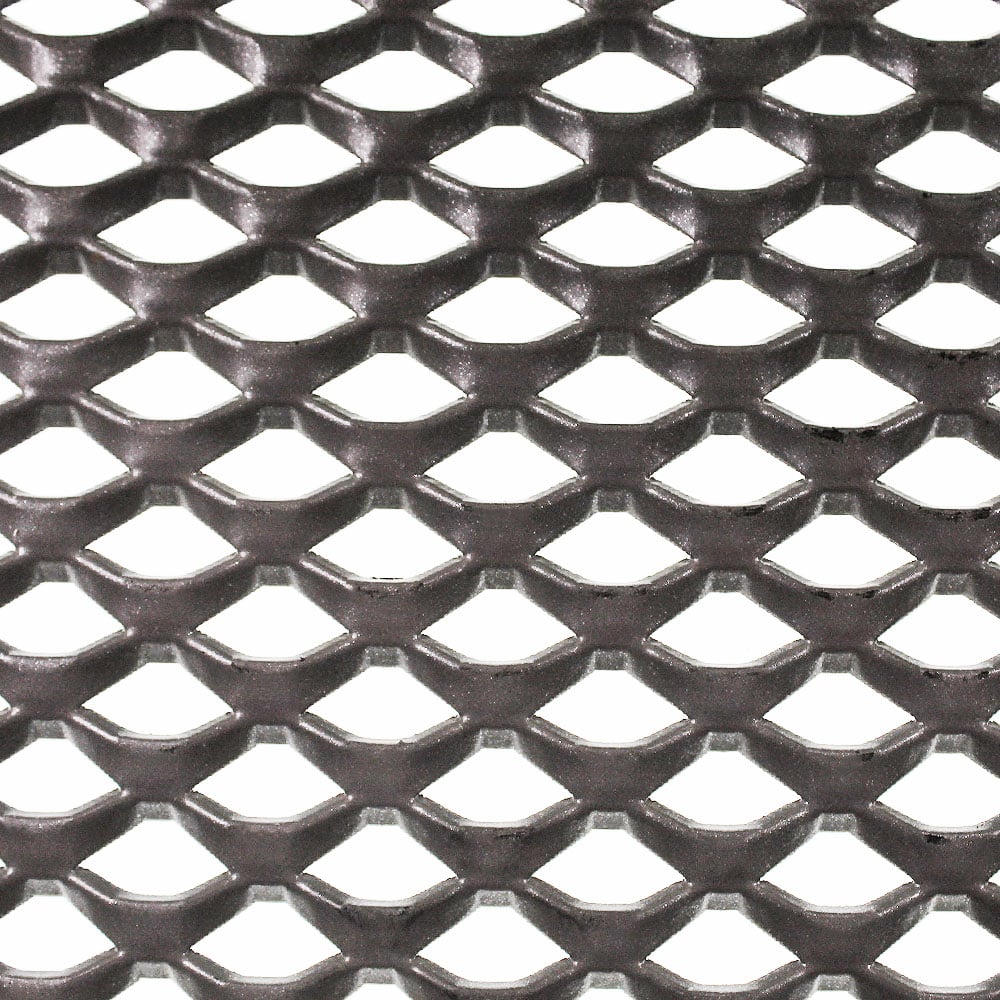

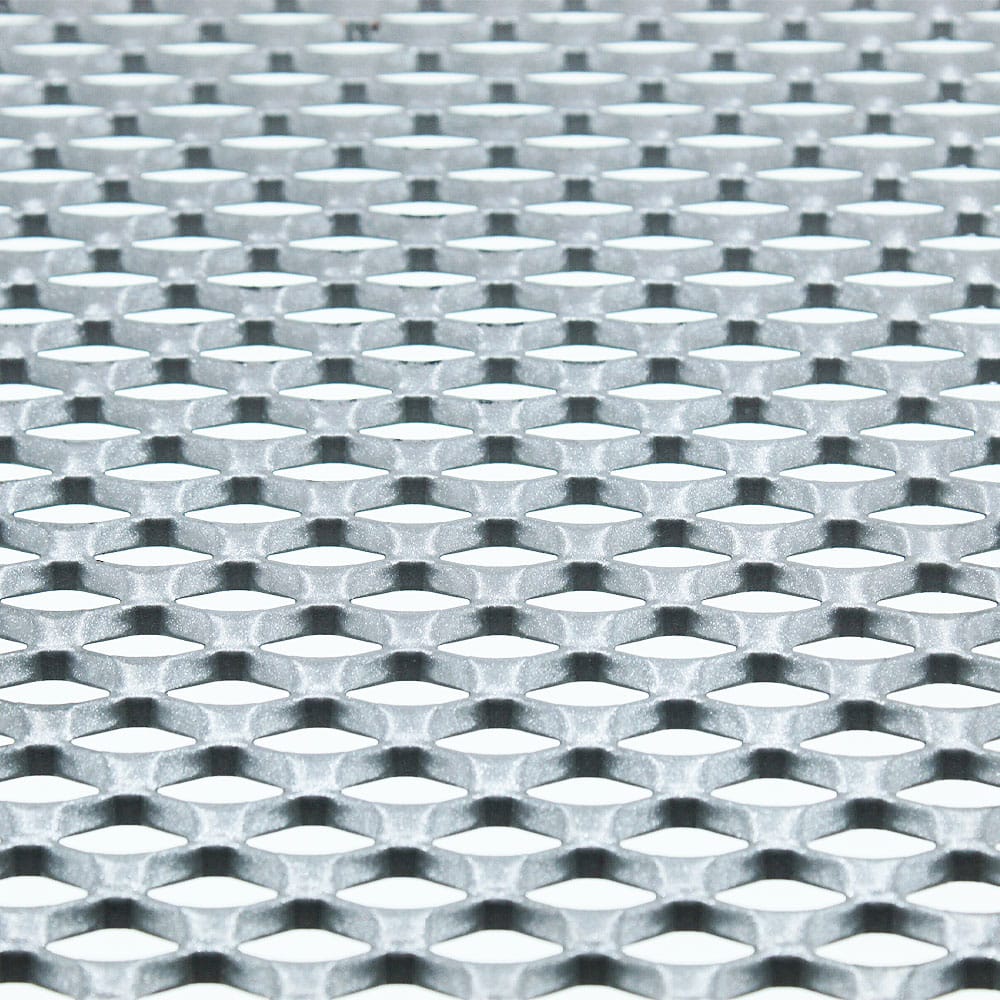

Its physical properties are great, but its aesthetic appeal is even better. Its modern and sleek appearance makes it a popular choice among architects and designers looking for a material that’s functional and looks good.

Adding an intriguing visual element to any structure, the diamond-shaped pattern of this expanded metal creates a sense of depth and texture. The way it plays with light and shadow gives it a dynamic quality, changing depending on the angle of light and the perspective of the viewer. In any architectural project, you can use this characteristic to create striking facades, decorative panels, or feature walls.

The aluminium expanded metal 10 x 8mm has been used in a lot of architectural projects. As an example, when used as cladding on modern buildings, it provides a protective layer and adds to the building’s overall aesthetic, making it look modern and sophisticated. This material has also been used in interior design to create unique ceiling designs, partition walls, and decorative panels.

Our architectural division offers a wide range of expanded metal solutions. If this is something that you wish to discuss then please contact them here. They will be delighted to discuss your project with you in depth.

Aluminium expanded metal offers remarkable versatility, finding use across a wide range of industries. Its strength, lightweight nature, and aesthetic appeal make it suitable for a wide range of applications, from purely functional to highly aesthetic.

Construction applications include facades, balustrades, and security fencing. The structural integrity and aesthetic qualities of this material make it an ideal choice for both exterior and interior architectural elements. Among its uses in the automotive industry are grilles and filters, where its strength and airflow properties are crucial.

The aerospace industry also benefits from the use of aluminium expanded metal. In this sector, where weight reduction without compromising strength is a constant challenge, its lightweight property is crucial. In aircraft construction, the material is used in ventilation systems and protective panels.

The visual appeal of aluminum expanded metal makes it a popular decorative material. With its unique pattern and texture, it adds an artistic touch to artworks, furniture, and design elements.

In order to maintain the integrity of expanded metal and achieve the desired shape and size, specific cutting and fabrication techniques are required. Cutting expanded metal mesh requires the following considerations and steps:

Choosing the Right Tools: Use tools that are appropriate for cutting metal, such as angle grinders, nibblers, or tin snips. For larger or more precise cuts, specialised cutting tools like plasma cutters can be used.

Measuring and Marking: Accurately measure and mark the area to be cut. It’s important to consider the pattern of the mesh to ensure that the final piece aligns with the intended design or application.

Cutting Process: When cutting, it’s crucial to maintain a steady hand and follow the marked lines closely. If using power tools, ensure they are set at the correct speed and use protective gear such as gloves and safety glasses.

Deburring Edges: After cutting, the edges of the mesh can be sharp and uneven. Deburring these edges is essential for safety and for a clean finish. This can be done using a file or an electric deburring tool.

Fabrication and Installation: Once cut to size, the expanded metal can be fabricated or formed into the desired shape using bending tools or by hand, depending on the material’s flexibility and the complexity of the design.

Finishing: If required, finishing touches such as painting or coating can be applied to the cut expanded metal for additional protection or to match design aesthetics.

The environmental benefits of aluminium expanded metal go beyond its functionality and aesthetics. Recyclability is a key aspect of its eco-friendliness. The recycling process of aluminum uses only a fraction of the energy necessary to produce new aluminium, significantly reducing its environmental impact.

Expanded aluminium contributes positively to green building practices and sustainable development. As a lightweight product, it reduces transportation emissions, and it is durable, reducing the need for frequent replacements and reducing waste. Further, expanded metal is manufactured efficiently, producing little waste since it is cut and stretched rather than removed.

The use of expanded metal in construction and design projects aligns with the principles of sustainable building, offering an environmentally friendly and high-performing solution. Due to its commitment to sustainability, it is an ideal choice for projects aiming to achieve green certifications or to reduce their ecological footprint.

The authors would like to encourage our readers to consider 10 x 8mm aluminium expanded metal for their next project, regardless of whether it will focus on functionality, design, or sustainability of the environment. We are at your disposal if you would like information about our expanded metal products or need assistance in selecting the right expanded metal products to meet your specific needs.

If you would like more information or assistance, we are at your disposal.

Take a look at our expanded metal products and services, and let us help you find the perfect solution for your project.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that compares perforated and expanded metal mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.