Stainless steel mesh is widely used in industries such as construction, filtration, security, and food processing due to its strength, durability, and corrosion resistance. However, not all stainless steel meshes are the same. The grade of stainless steel used in the mesh plays a crucial role in determining its suitability for different environments and applications.

At The Mesh Company, we offer four main grades of stainless steel mesh:

✔ 304 Stainless Steel – Standard, general-purpose mesh.

✔ 316 Stainless Steel – Marine-grade for high corrosion resistance.

✔ 316L Stainless Steel – Lower carbon version of 316 for enhanced weldability.

✔ 430 Stainless Steel – Magnetic stainless steel with basic corrosion resistance.

In this guide, we will explain the differences between these grades and help you determine which type of stainless steel mesh is best suited for your needs.

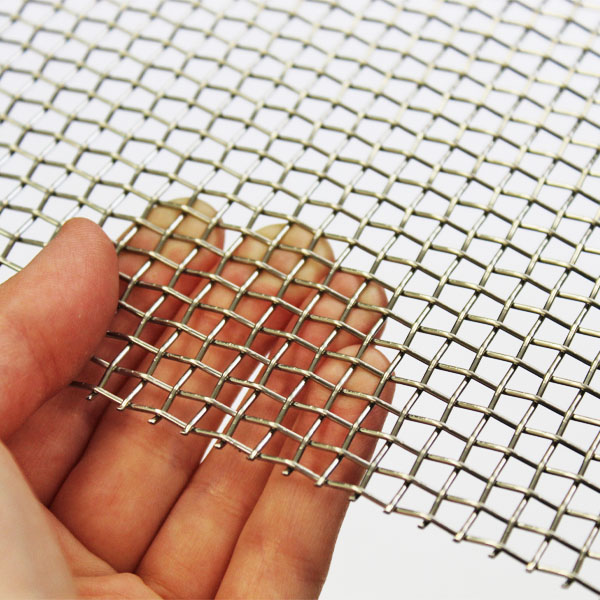

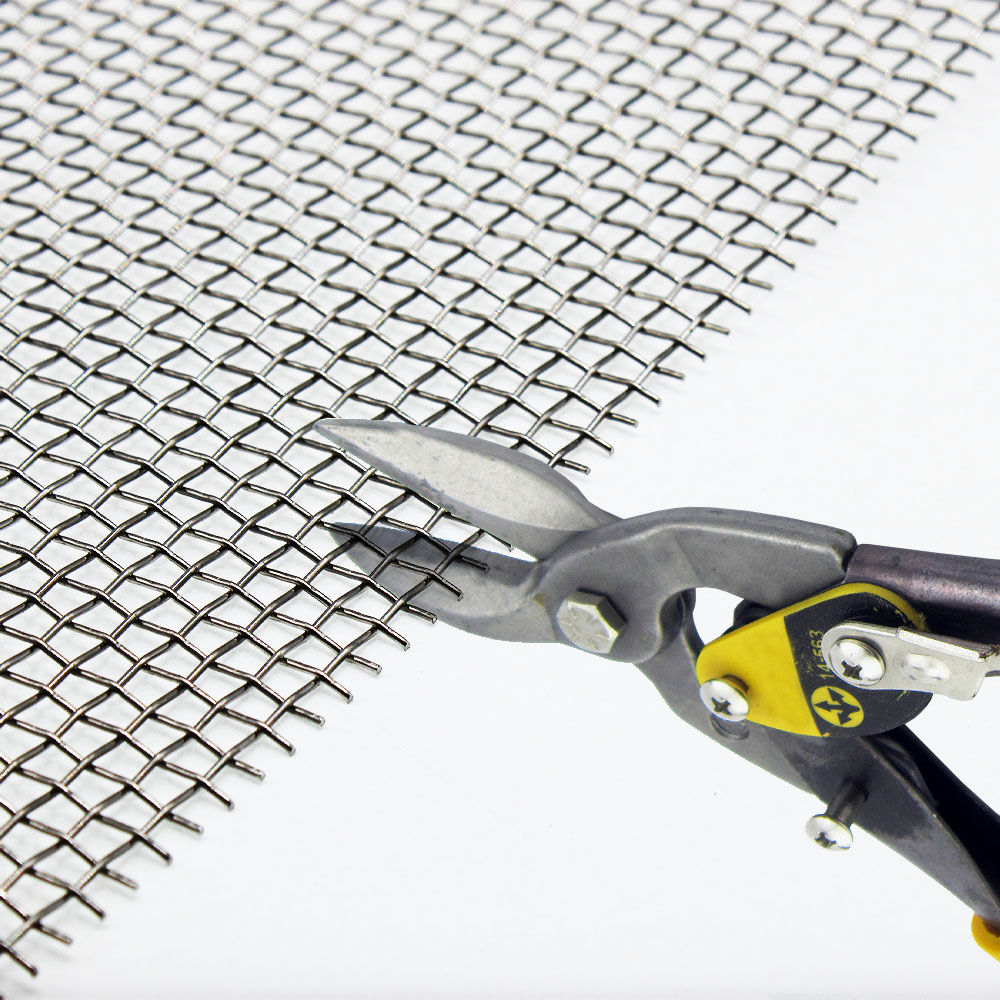

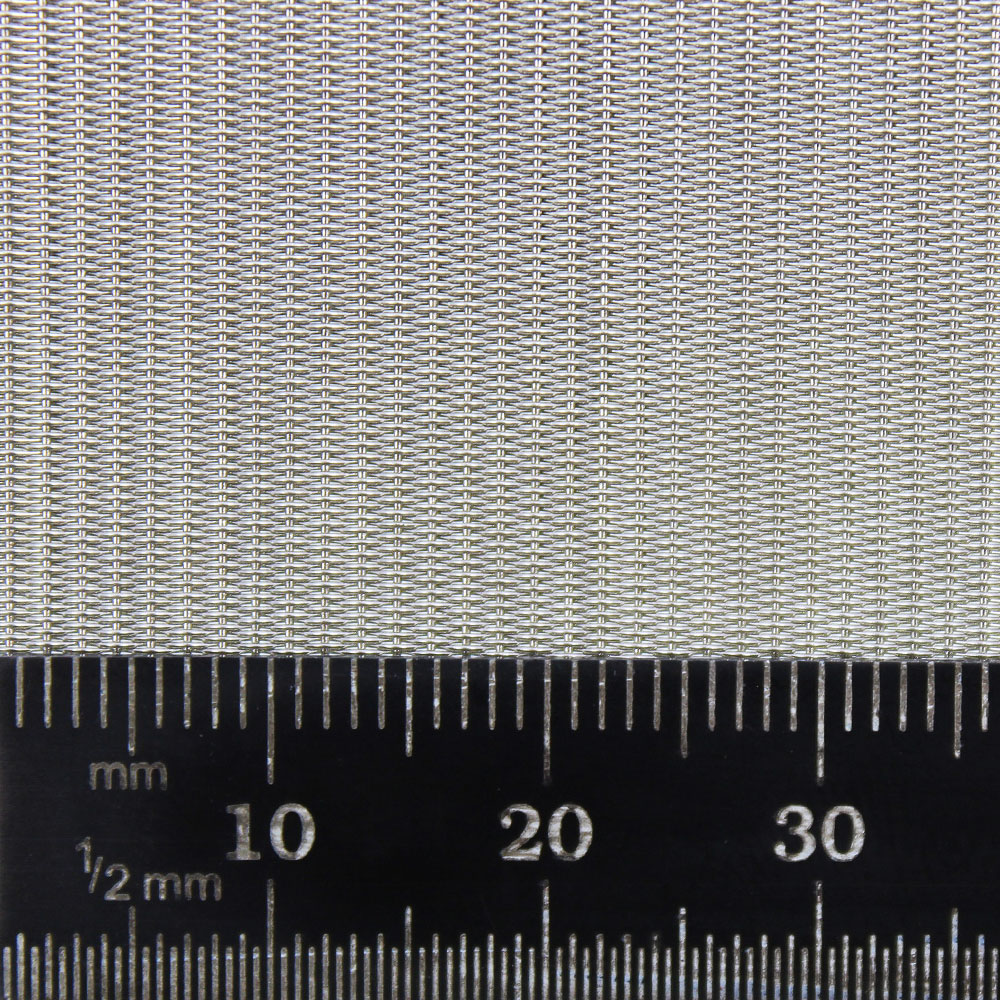

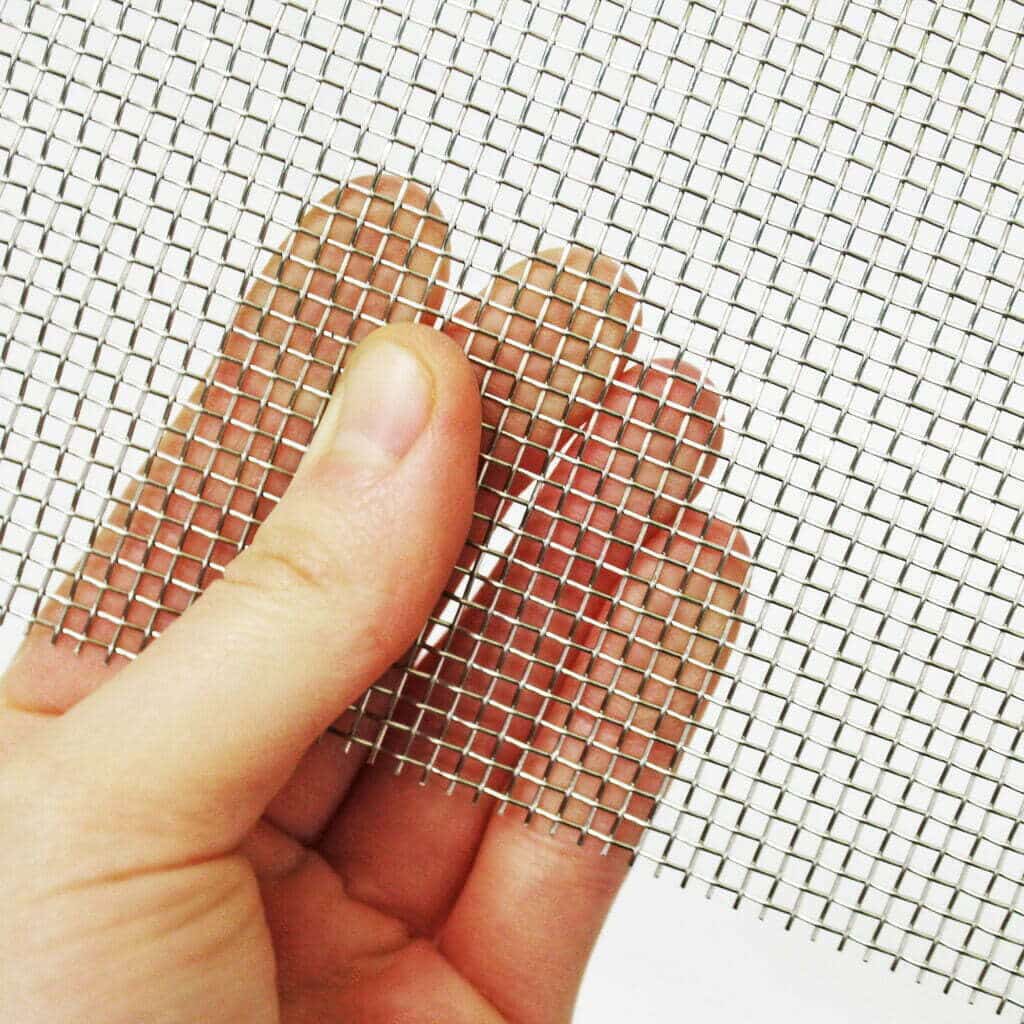

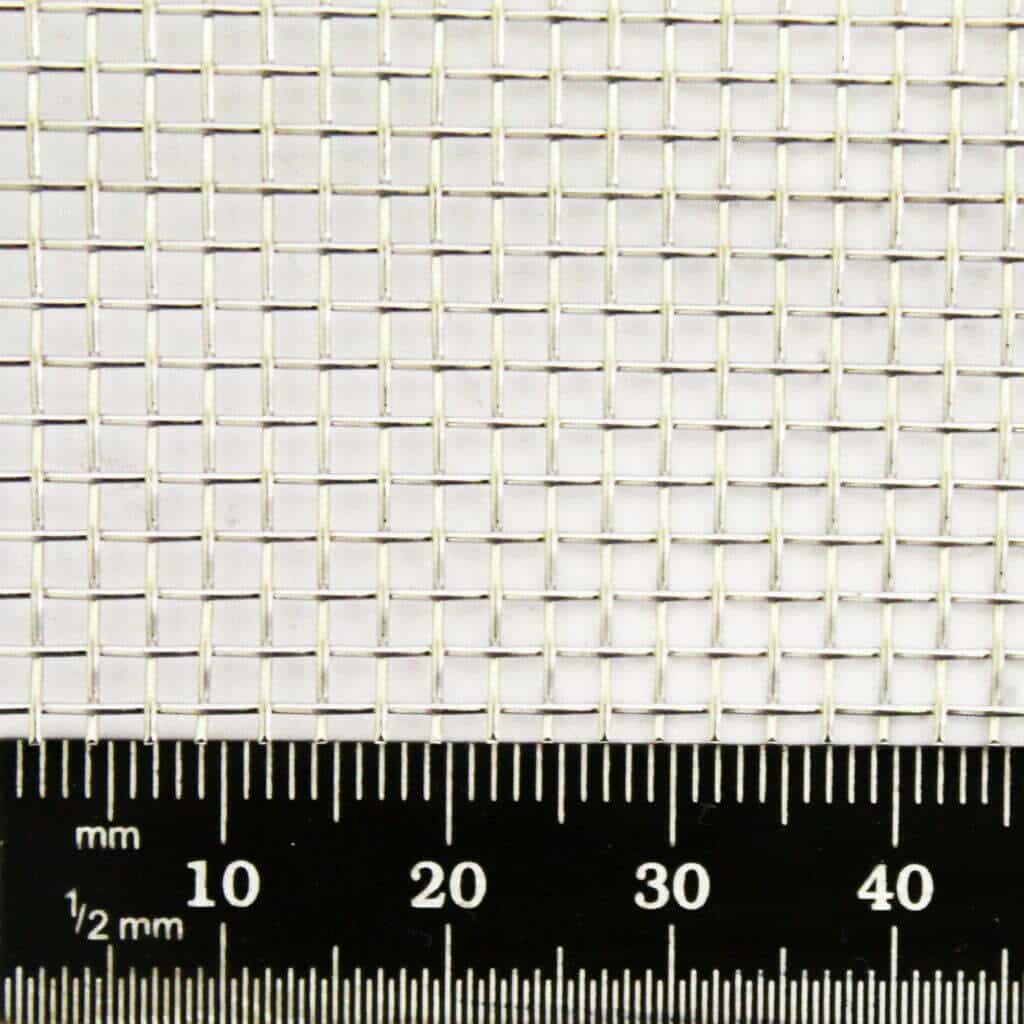

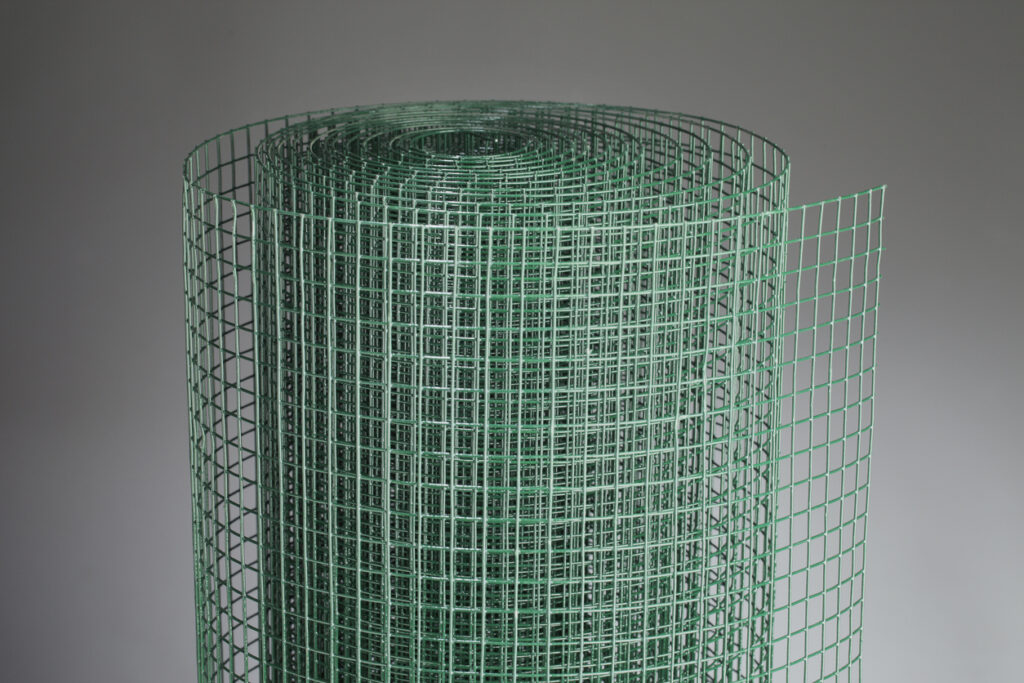

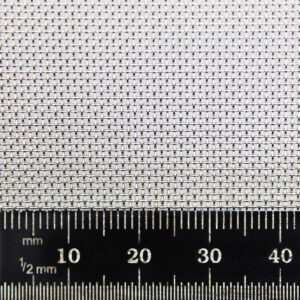

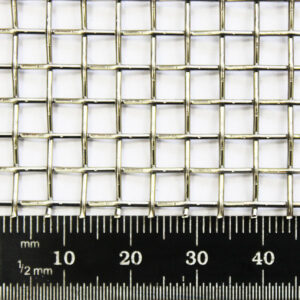

Stainless steel mesh is manufactured by weaving or welding thin steel wires together to form a durable and flexible material. The stainless steel composition provides excellent resistance to rust, corrosion, and high temperatures. Mesh specifications can vary based on hole size (aperture), wire diameter, and weave type.

Applications include:

✅ Best for general use

✅ Excellent corrosion resistance

✅ Affordable and widely available

304 stainless steel is the most commonly used stainless steel mesh. It contains 18% chromium and 8% nickel, which gives it excellent resistance to rust and oxidation under normal atmospheric conditions.

Best Applications for 304 Stainless Steel Mesh:

✅ Best for harsh environments

✅ Highly resistant to saltwater and chemicals

✅ Stronger corrosion resistance than 304

316 stainless steel contains 2-3% molybdenum, which significantly increases its resistance to corrosion—especially in marine, chemical, and saltwater environments. It is widely used in industries requiring superior durability.

Best Applications for 316 Stainless Steel Mesh:

✅ Same corrosion resistance as 316 but better for welding

✅ Lower carbon content prevents welding corrosion issues

✅ Ideal for industrial and manufacturing applications

316L stainless steel is a low-carbon variation of 316 stainless steel. The reduced carbon content prevents carbide precipitation, which can occur during welding, ensuring that the mesh remains corrosion-resistant after fabrication.

Best Applications for 316L Stainless Steel Mesh:

✅ Cost-effective stainless steel

✅ Magnetic properties (unlike 304 and 316)

✅ Moderate corrosion resistance

430 stainless steel is a ferritic stainless steel, meaning it contains no nickel. It has good corrosion resistance in dry conditions but is less durable in wet or salty environments. However, its magnetic properties make it useful for specialist applications.

Best Applications for 430 Stainless Steel Mesh:

| Grade | Strength | Corrosion Resistance | Best Use Case | Price |

|---|---|---|---|---|

| 304 | High | Good (not saltwater-resistant) | General use, filtration, insect mesh | ££ |

| 316 | Very High | Excellent (best for marine/saltwater) | Food, medical, marine environments | £££ |

| 316L | Very High | Excellent (best for welding) | Industrial welding, chemical resistance | £££ |

| 430 | Medium | Moderate (dry use only) | Budget-friendly, magnetic properties | £ |

When selecting a stainless steel mesh, consider the following:

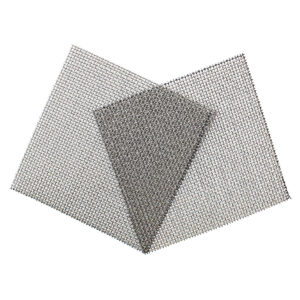

At The Mesh Company, we stock a wide range of stainless steel meshes in different grades, sizes, and specifications. Whether you need fine filtration mesh, heavy-duty security mesh, or marine-grade protection, we have the perfect solution for your project.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions