Wire mesh filtration is a crucial component in industrial, commercial, and residential applications, influencing everything from air quality to liquid purification and particulate separation. The science behind mesh density, airflow resistance, and filtration efficiency is key to selecting the right type of mesh for various uses.

At The Mesh Company, we specialise in high-quality wire mesh solutions that balance strength, airflow, and filtration efficiency. In this article, we will explore:

At The Mesh Company, we specialise in high-quality wire mesh solutions that balance strength, airflow, and filtration efficiency. In this article, we will explore:

Whether you are looking for air filters, liquid strainers, or high-precision filtration systems, this guide will help you make an informed choice.

Mesh density refers to the number of wires per inch in a given wire mesh. It directly influences:

✔ Filtration efficiency – The ability to capture fine particles

✔ Airflow and permeability – How easily air or liquid passes through

✔ Structural strength – The durability of the mesh under pressure

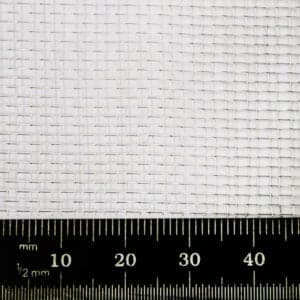

Mesh density is measured in two primary ways:

High-density wire mesh provides better filtration but can also reduce airflow, creating resistance. This is crucial for applications like:

To optimise both filtration and airflow, selecting the right mesh density is essential.

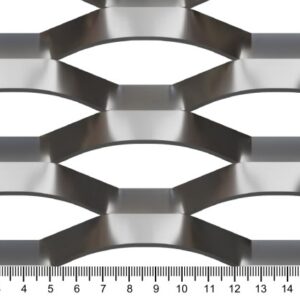

Wire mesh filters trap particles based on aperture size, wire thickness, and weave type. The principle is simple:

Wire mesh is used in:

To select the best wire mesh filtration solution, consider the following:

Consider exposure to chemicals, moisture, or extreme temperatures to ensure the chosen mesh can withstand environmental conditions.

Balancing airflow and filtration is essential for industries like HVAC, automotive, and industrial processing. Here’s how:

✔ Use multi-layered mesh – A combination of coarse and fine mesh improves efficiency

✔ Select the right aperture size – Avoid unnecessary resistance while still trapping contaminants

✔ Ensure correct tensioning – Loose mesh may vibrate, reducing efficiency

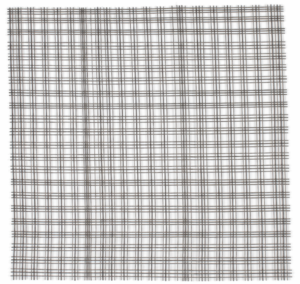

✔ Choose the right weave pattern – Dutch weave improves particle retention, while plain weave maintains airflow

Proper maintenance extends the life of wire mesh filtration systems.

✔ Rinse with water – Removes dust and debris from air filters

✔ Ultrasonic cleaning – Best for fine mesh used in liquid and pharmaceutical filtration

✔ Compressed air blowing – Removes fine particles from industrial sieves

✔ Chemical cleaning – Used for oil and grease removal (ensure compatibility with mesh material)

At The Mesh Company, we provide premium-quality wire mesh for filtration applications, catering to industrial, commercial, and residential needs.

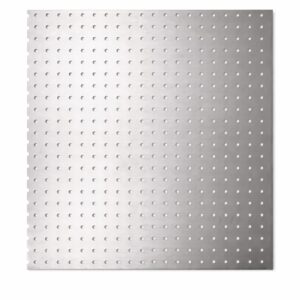

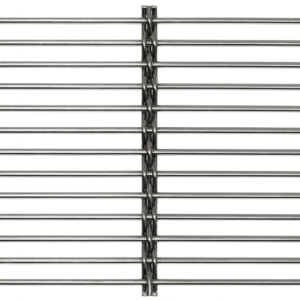

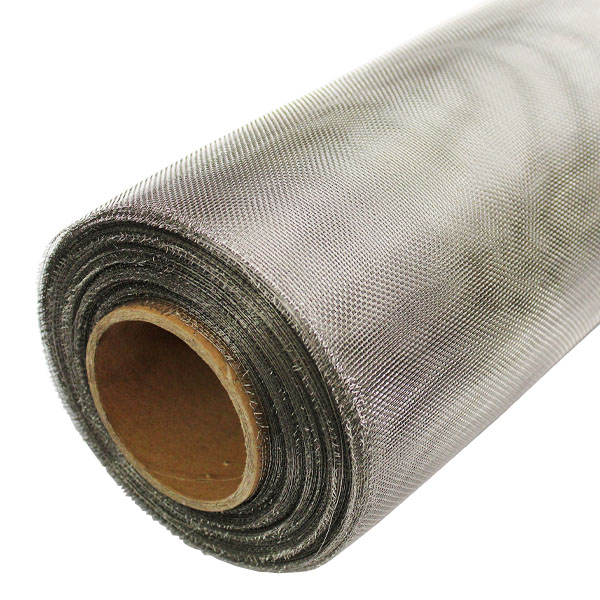

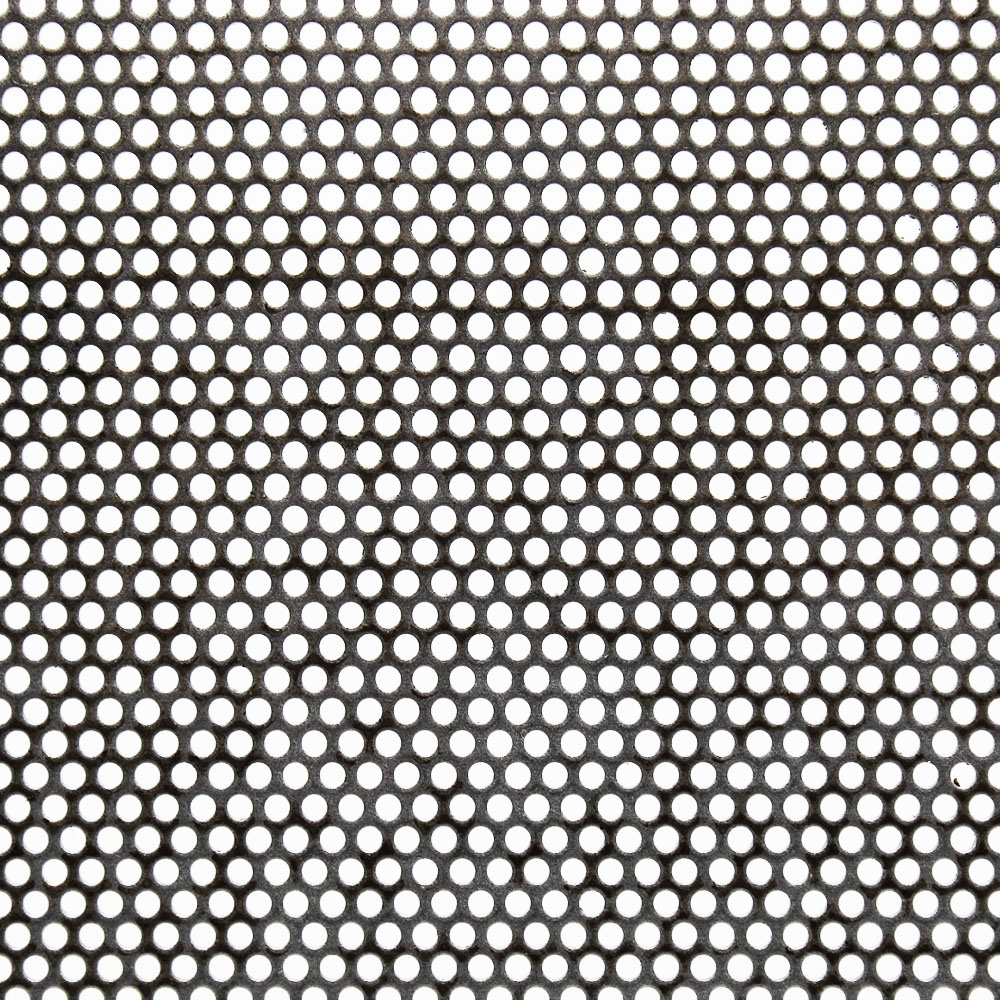

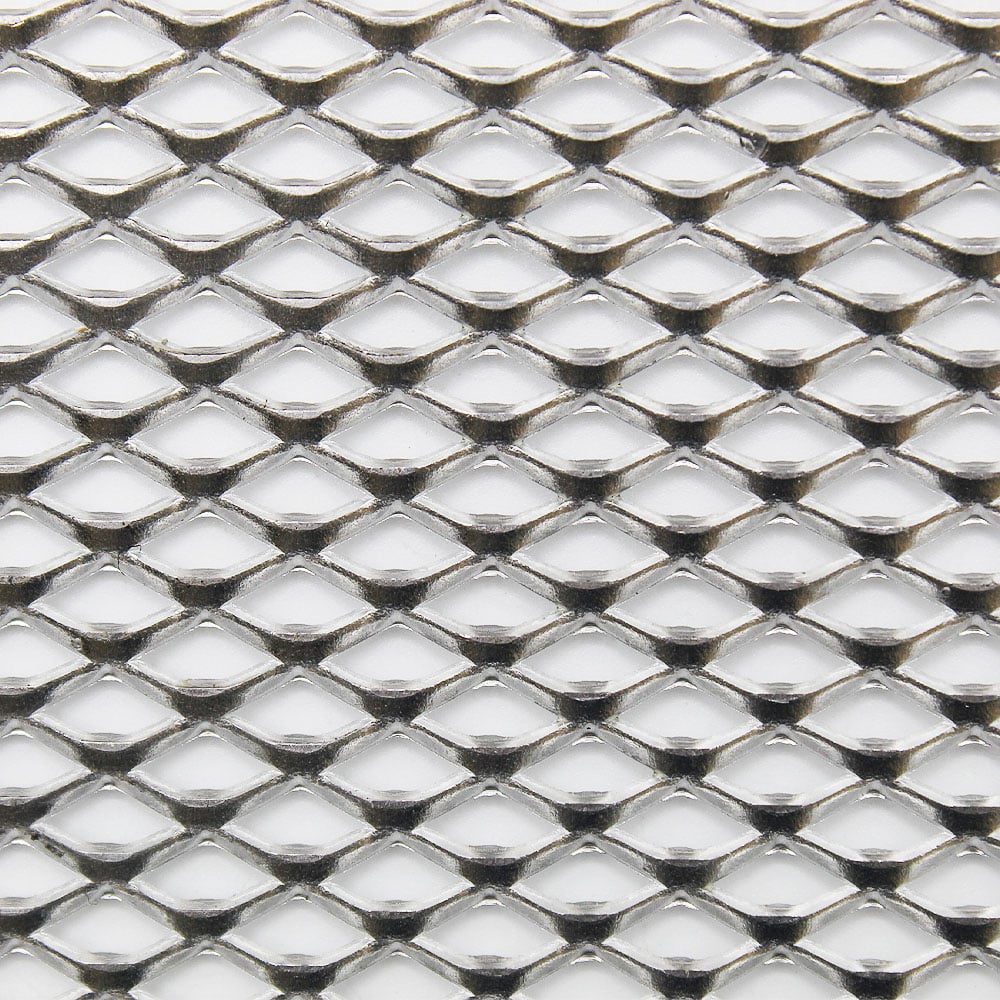

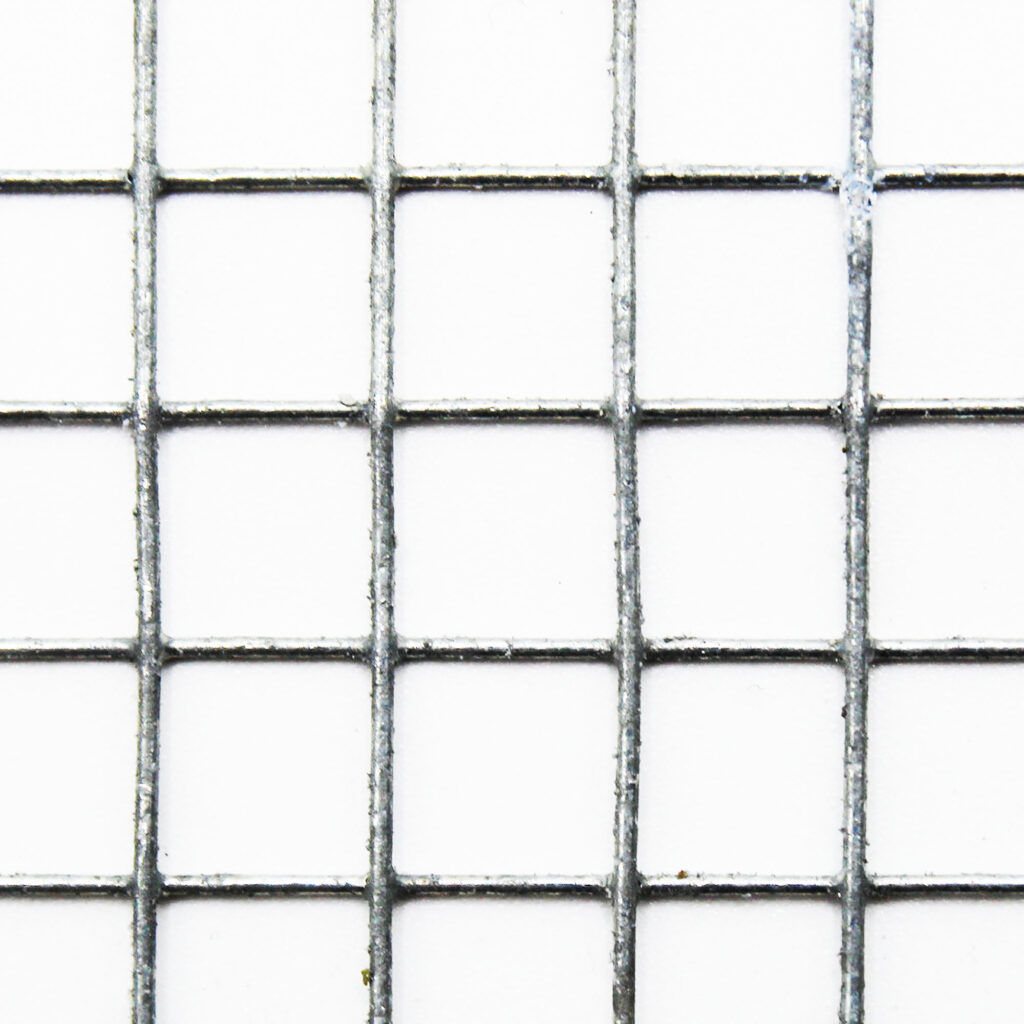

✔ Wide Range of Filtration Mesh Options – Woven, perforated, and welded mesh available

✔ Custom Fabrication – Tailored solutions for bespoke applications

✔ High-Quality Materials – Corrosion-resistant stainless steel, brass, and copper options

✔ Fast UK Delivery – Quick turnaround times for all orders

Explore our extensive range at The Mesh Company or contact our experts for guidance.

Understanding wire mesh filtration and mesh density’s impact on airflow is crucial for selecting the right material. Whether for HVAC systems, water filtration, or industrial sieving, choosing the correct wire mesh ensures optimal efficiency and durability.

For high-quality wire mesh solutions, visit The Mesh Company and find the perfect filtration solution today.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.