Expanded metal mesh is an incredibly versatile material with a variety of applications, from architecture to industrial equipment. We are currently in the process of opening up our stocks to the general public for the first time, so we will be adding loads of new options in the coming weeks.

But did you know that there are two distinct types of expanded metal mesh?

In this blog post, we’ll explain the differences and the potential uses of raised and flattened expanded metal mesh, so you can decide which type is right for your project.

Let’s get into it…

The primary difference between raised and flattened expanded metal mesh is the shape of the diamond pattern created by the strands.

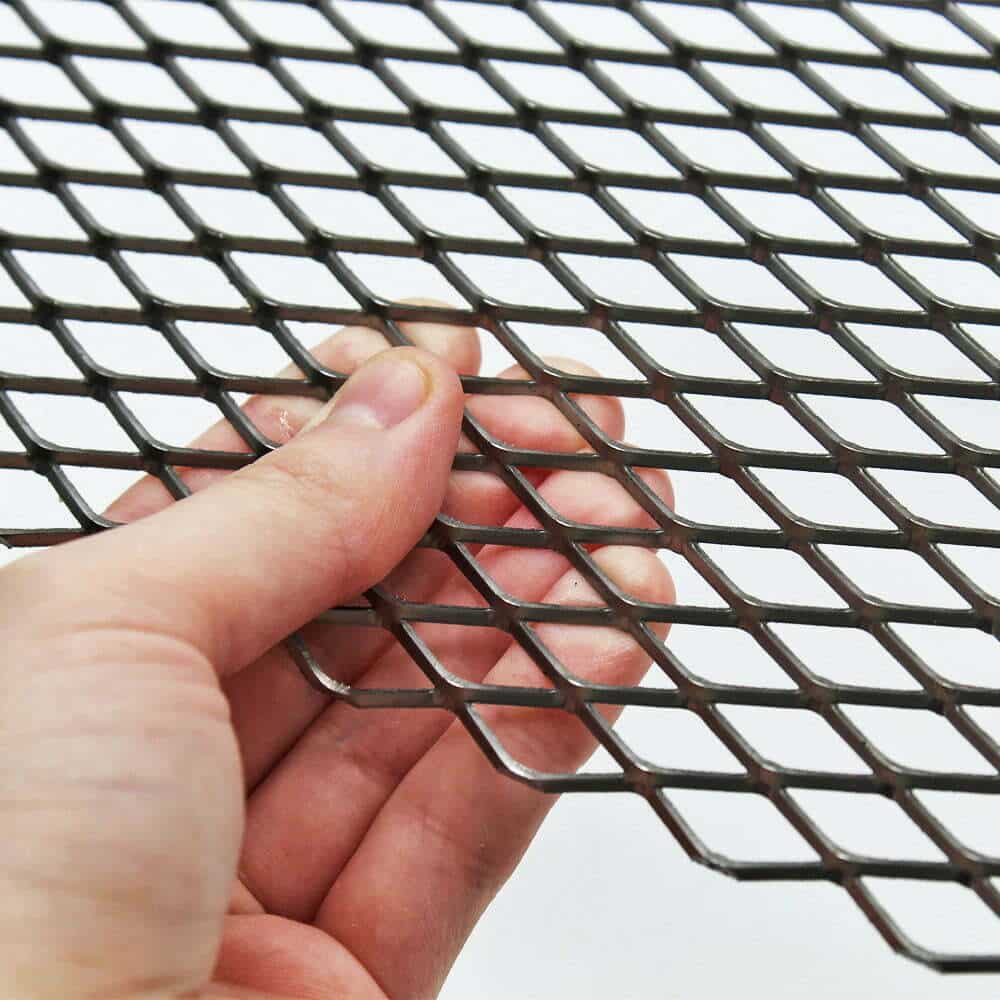

Raised expanded metal mesh has a 3D structure with projections that extend outward from the plane of the material. This structure gives it greater rigidity, which makes it ideal for use in many industries where support and strength are required. It also provides a larger surface area for powder coating or other decorative finishes. This is a common use for our EPM.

Conversely , flattened expanded metal mesh has been cold-rolled to flatten out the diamond pattern and create an even surface with no projections. This makes it more suitable for applications where a smooth surface is desired, such as in architectural grilles or railings.

Regardless of whether you choose raised or flattened expanded metal mesh, both offer several advantages over traditional solid sheet materials such as steel or aluminium.

Most importantly, it’s much lighter than its solid sheet counterparts, making it ideal for applications where weight needs to be at a premium.

It’s also much stronger than most mesh options, and its increased rigidity means that it can hold up better to heavy loads while still maintaining its shape and structural integrity.

Quite simply, flattened EPM is preferable to projects that require strength and a flat surface.

Similarly to some of our heavy duty mesh specs, flattened expanded metal is often used as a flooring material because of its smooth surface, which makes it easy to walk on. It also provides good traction, which is important for safety.

It can be a better choice for filtration applications because of its smooth surface, which allows it to trap particles more effectively. It can also be easier to clean and maintain than raised expanded metal. Again., in this way it is much more similar to heavy duty woven wire mesh or standard perforated metal specifications.

It can be a better choice than raised expanded metal for applications where noise reduction is important, such as acoustic panels or barriers. The smooth surface of flattened expanded metal can help to absorb sound waves more effectively than the raised pattern of expanded metal.

Raised pretty much provides the opposite set of benefits.

It is great in situations where ventilation is important. The raised pattern allows for better airflow than flattened expanded metal, which can help to regulate temperature and reduce the risk of moisture build-up.

It is often used for security applications, such as fences or window guards, because of its strength and durability. The raised pattern can also help to deter intruders by making it more difficult to climb.

It is also more commonly used for architectural facades. Check out this famous project that our architectural division delivered at Headingley Cricket Ground a few years ago. This is a classic example of raised expanded being used to provide a quality solution for an external cladding requirement.

Expanded metal mesh is one of the most versatile materials available today due to its unique combination of light weight, strength, and cost effectiveness. It is only rivalled by perforated metal when it comes to strength at such a light weight.

Whether you’re looking for something with greater rigidity or a smooth surface finish, there’s bound to be an option that meets your needs.

Please be patient while we extend our range. We are aiming to add 1 new specification every week until we have the full array available. Thank you

For more information on which type might be best suited for your application please reach out to our experts today!

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions