At The Mesh Company, we spend a lot of time bridging the gap between specialist mesh products and real-world requirements. Not everything needs to be an architectural façade or a bespoke specification – but that doesn’t mean customers shouldn’t have access to genuinely high-quality materials.

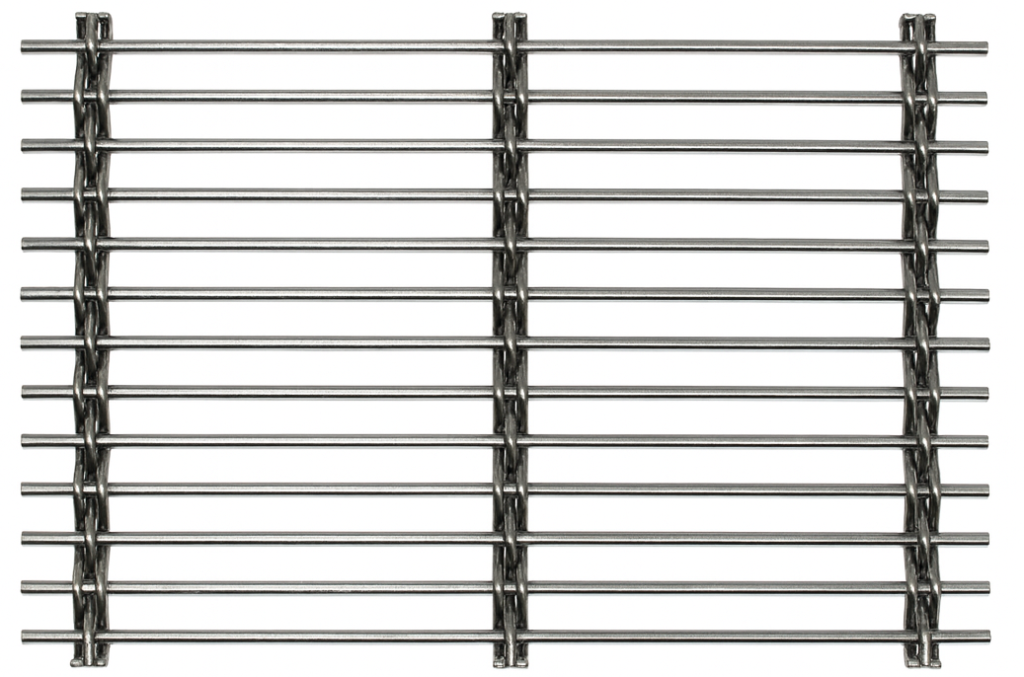

That’s exactly why we’re pleased to introduce our 316L stainless steel pre-crimped wire mesh with an 80 × 10mm pattern into our e-commerce range.

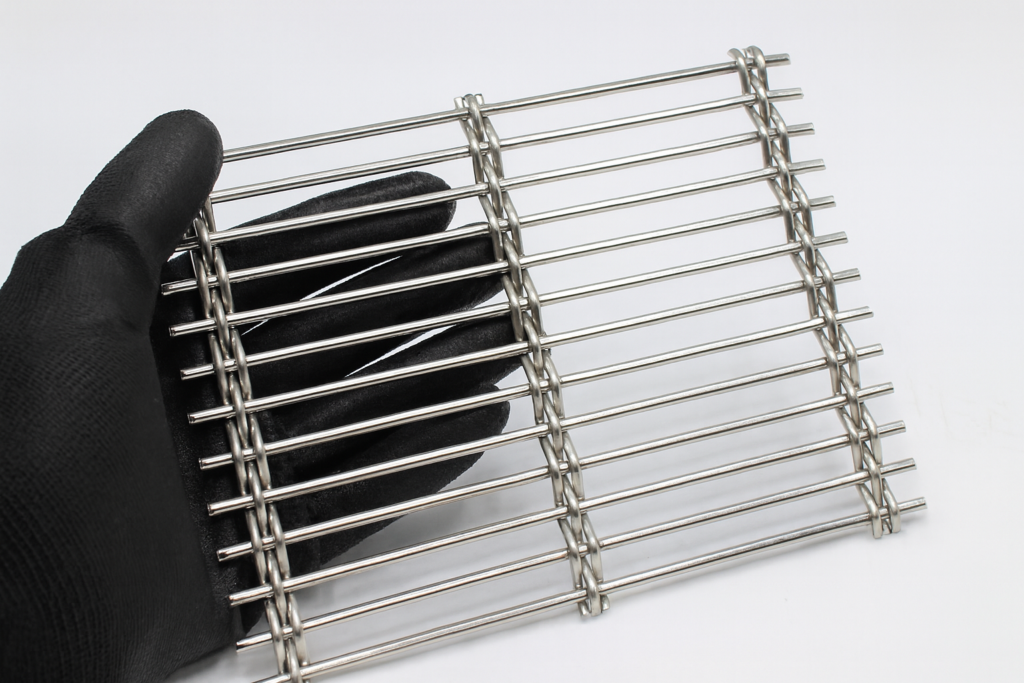

This is a serious, heavy-duty woven mesh, supplied in practical sizes, available for fast dispatch, and suitable for customers who need strength, rigidity and longevity without stepping into full architectural procurement.

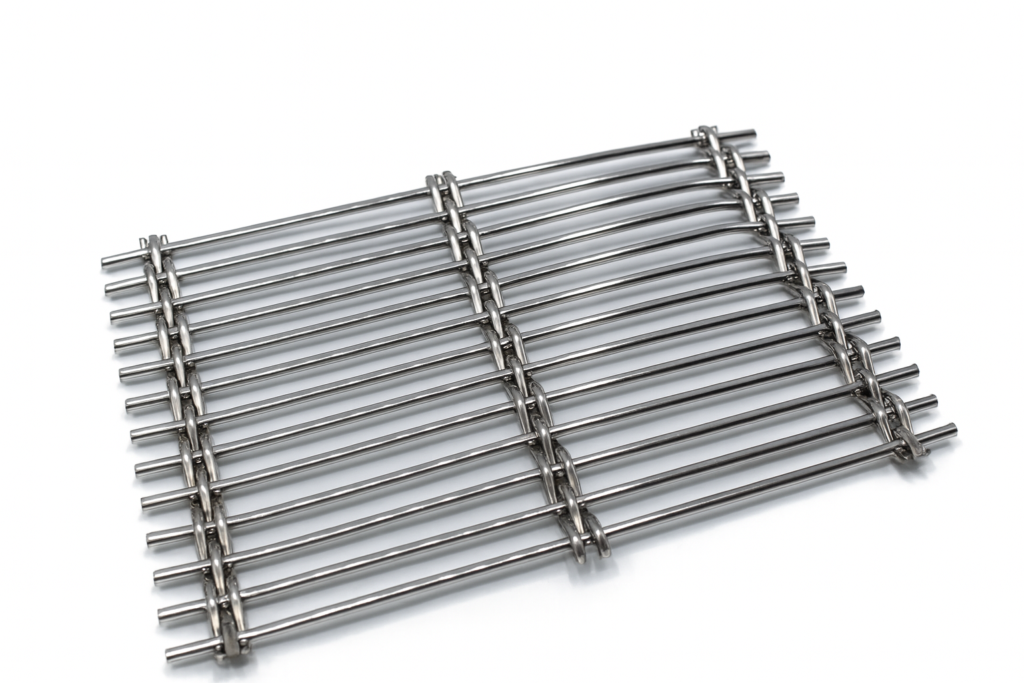

Pre-crimped wire mesh is produced by forming each wire with a crimp before weaving, rather than relying on tension alone to hold the structure together. The result is a mesh that behaves more like a rigid panel than a flexible fabric.

Unlike standard woven mesh, where wires can shift slightly under load, pre-crimped mesh locks into place. Once woven, the structure is stable, strong, and highly resistant to deformation.

In simple terms:

That makes this type of mesh particularly well suited to applications where rigidity matters.

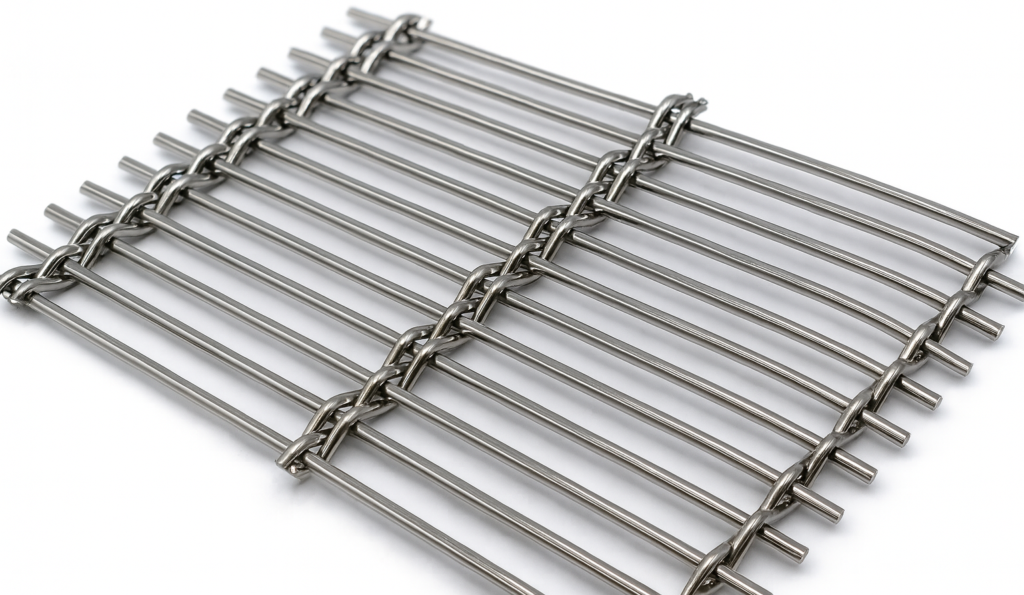

The “80 × 10” designation refers to the pitch, not the clear aperture. This is an important distinction and one that often causes confusion.

Because this mesh evolved from cable-based architectural systems, it has retained pitch-based naming rather than aperture-based naming. In reality, the clear openings are irregular, but that’s exactly what gives this mesh its distinctive strength and appearance.

Visually and structurally, it behaves much more like a rigid grid or panel than a traditional mesh.

his is not a lightweight product.

The structure consists of:

When you pick this mesh up, it immediately feels different. There is very little flex, and it resists distortion far more than welded mesh or standard woven mesh of a similar openness.

This makes it ideal where:

We’ve chosen to supply this mesh in 316L stainless steel for a reason.

316L offers:

For customers who are installing mesh in exposed areas, plant rooms, vents, outdoor enclosures, or anywhere longevity matters, 316L is the right choice.

This is a material that’s designed to last.

Although this pattern originates from architectural design, there are plenty of practical, real-world uses that make sense for our retail customers.

Common applications include:

Heavy-Duty Vent Covers and Screens

Where airflow is needed but strength cannot be compromised – for example, plant rooms, generator housings, or industrial ventilation openings.

Security and Protective Panels

Ideal for covering openings, creating barriers, or protecting equipment without fully enclosing it.

Industrial and Workshop Use

Used as guards, partitions, or infill panels where rigidity is essential.

Infrastructure and Utility Projects

For covers, protective screens, or access protection where standard mesh would be too flexible.

Specialist DIY and Fabrication Projects

For customers who are fabricating frames, grilles, or one-off installations and want a mesh that behaves like a structural component.

This is not decorative mesh in the traditional sense – it’s a functional, structural product.

At The Mesh Company, our focus is on:

This product fits perfectly into that model.

We supply it in manageable sizes, suitable for:

You don’t need to be ordering hundreds of square metres to access this level of quality.

It’s natural to compare this mesh to welded mesh, as both are rigid.

The difference is significant:

For demanding environments, pre-crimped mesh often outperforms welded alternatives.

This mesh is ideal if:

It’s probably not the right choice if:

That’s why we offer such a wide range – different meshes exist for different jobs.

The introduction of the 316L pre-crimped 80 × 10mm wire mesh gives our customers access to a genuinely heavy-duty product that sits above standard woven and welded mesh, without pushing them into architectural procurement.

It’s strong, rigid, corrosion-resistant, and designed for real-world use.

If you need a mesh that feels like a panel, performs like a barrier, and lasts like stainless steel should – this is one worth serious consideration.

Chris Platt – Director