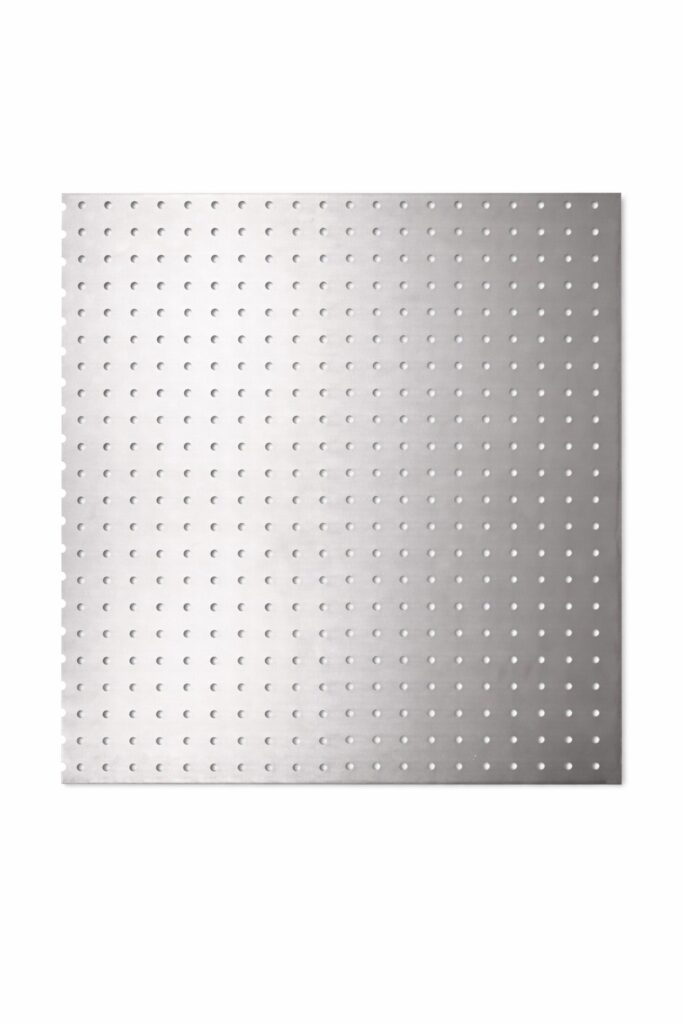

Stainless steel perforated metal sheet is a versatile and durable material that can be used in a variety of applications such as screens, filters, facades, and panels, among others.

However, not everyone is familiar with this material, its advantages, and its uses.

In this article, we will provide you with everything that you need to know about stainless steel perforated metal sheet, from its definition to its properties, manufacturing process, applications, and buying tips.

Let’s get into it….

Stainless steel perforated metal sheet is made through a process of punching or stamping holes into a flat sheet of stainless steel.

The process begins with a coil or sheet of stainless steel that is flattened and cleaned to remove any debris or impurities.

The stainless steel sheet is then fed through a machine that uses a punch or stamp to create the desired pattern of holes. This is known as a perforating press.

The size, shape, and spacing of the holes can be customised to meet specific requirements. After the perforations are made, the sheet is usually cleaned and inspected for any defects before it is ready for use.

The resulting perforated metal sheet is strong and durable.

The sheet metal itself can be made of different grades of stainless steel, such as 304, 316, or 430, each with its own corrosion resistance, strength, and surface finish. The Mesh Company supplies top quality 304 stainless steel metal mesh.

Stainless steel perforated metal sheet has several advantages over other materials such as aluminium, copper, or plain steel.

304 stainless is highly resistant to corrosion, abrasion, and heat, making it suitable for outdoor and high-temperature environments.

It is also strong, lightweight, and easy to fabricate and install, reducing the cost and time of construction.

In addition, stainless steel perforated metal sheet offers good acoustic and ventilation properties, allowing for airflow and sound absorption. We recently produced an article outlining how perforated metal mesh can be used for acoustic applications.

Stainless steel perforated metal sheet is manufactured through a series of processes. The whole process begins with the selection of the raw material and the design of the perforation pattern.

The sheet metal is then loaded onto a perforation press that punches or drills the desired holes into it, using a die and a punch.

The spacing, size, and shape of the holes can be adjusted by changing the position and the shape of the die and the punch. It is a bit like using an incredibly strong and accurate cookie-cutting tool. But for sheet metal.

After perforation, the sheet metal is trimmed, cleaned, and possibly coated or painted, depending on the application.

Stainless steel is most costly to produce than aluminium, galvanised or plain steel. So consider these alternatives if you are working on a tight budget.

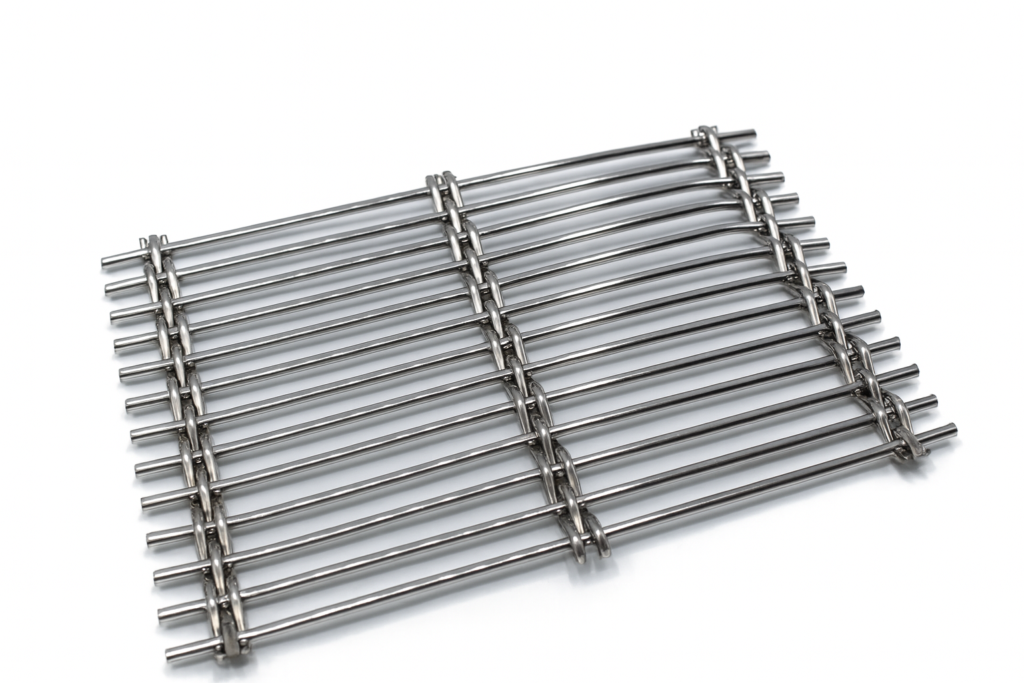

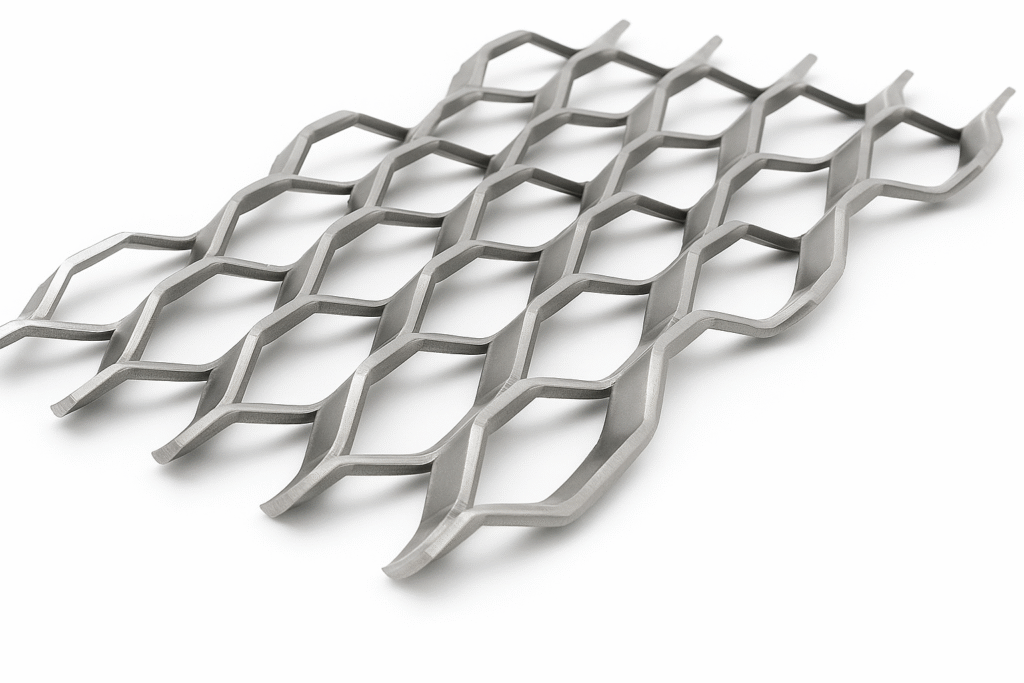

Stainless steel perforated metal sheet has a wide range of applications in various industries and fields, such as architecture, construction, automotive, electronics, food processing, and healthcare.

It can be used as decorative and functional elements in building facades, balustrades, sunshades, and screens, providing privacy, shade, and ventilation.

It can also be used as filters, strainers, diffusers, and noise barriers in HVAC systems, water treatment plants, and industrial processes.

Furthermore, stainless steel perforated metal sheets can be used as speaker grills, oven racks, baking trays, and medical implants, among others.

It is likely the most versatile of all perforated metal options.

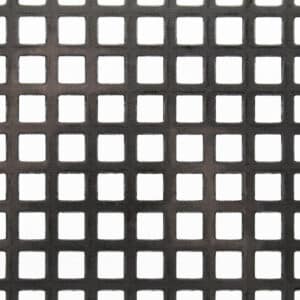

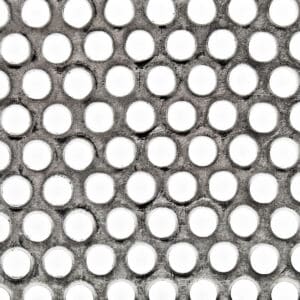

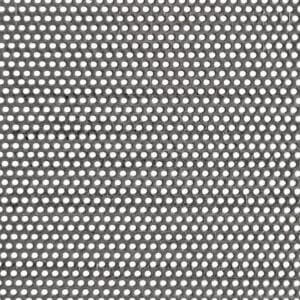

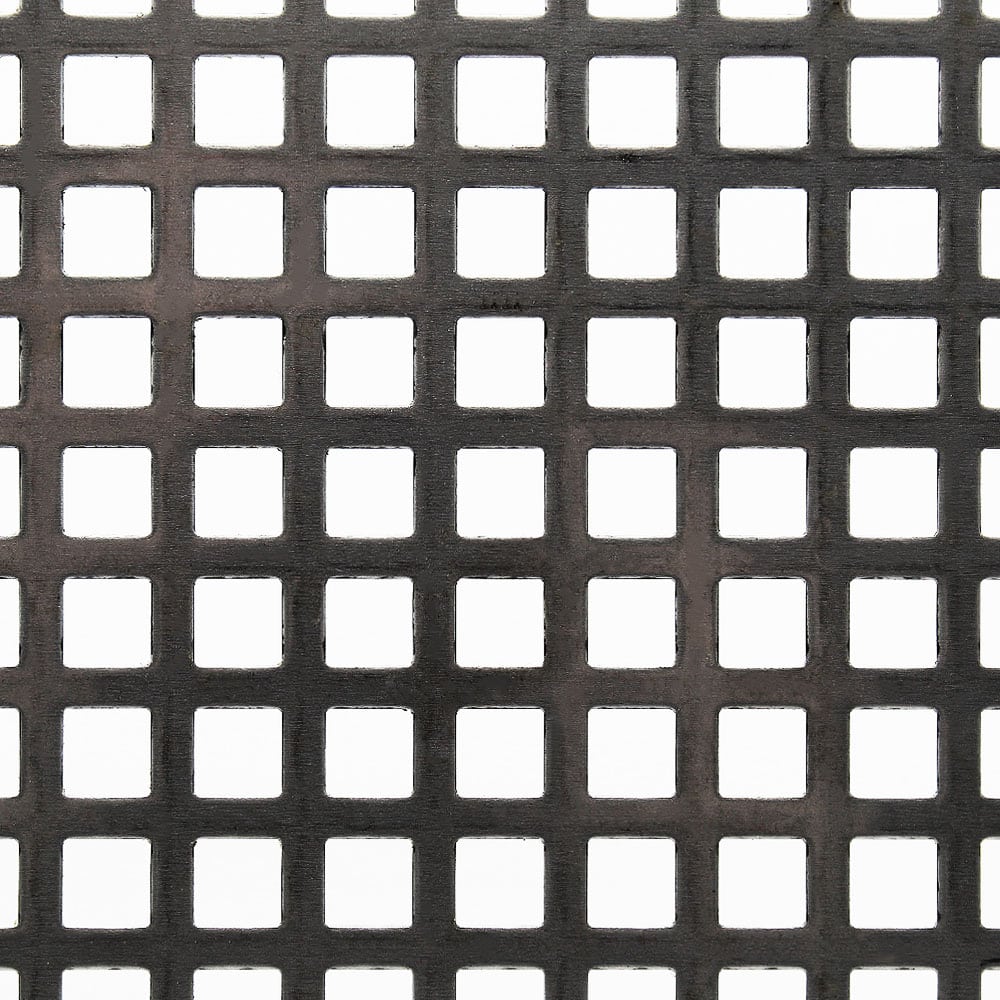

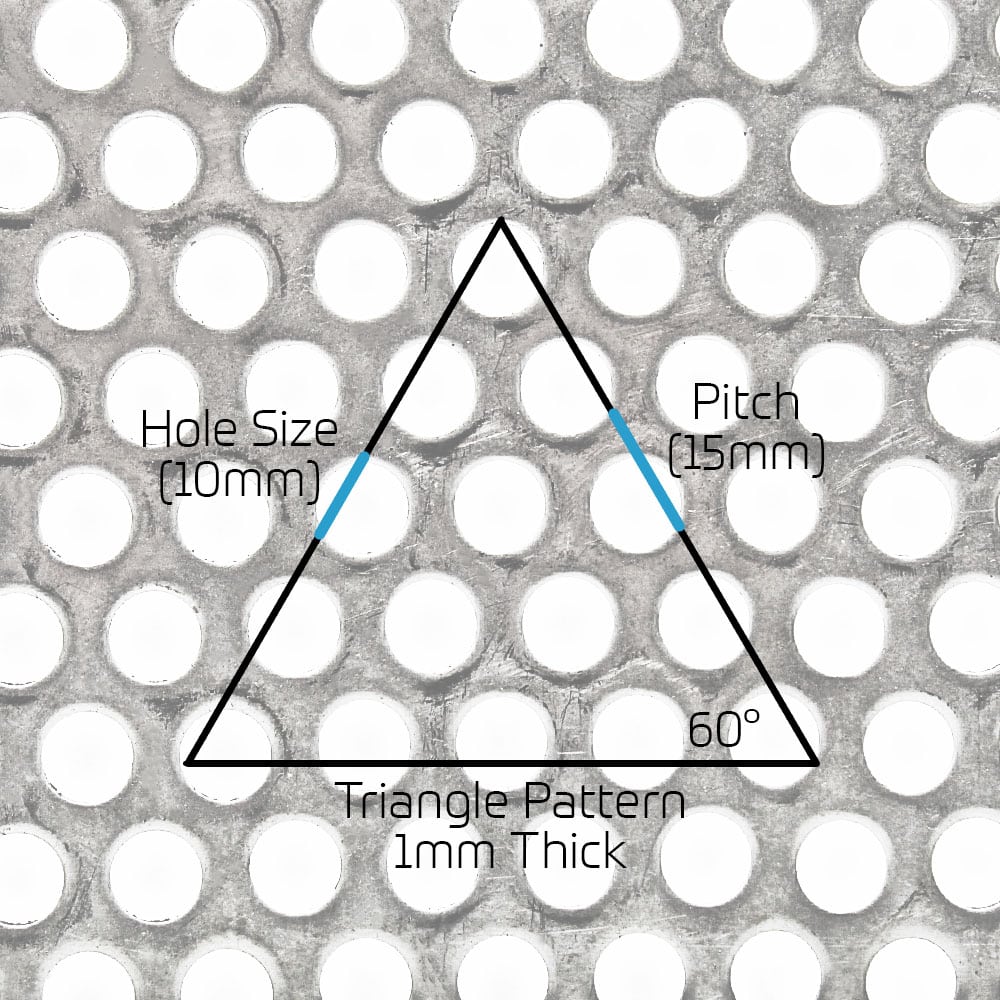

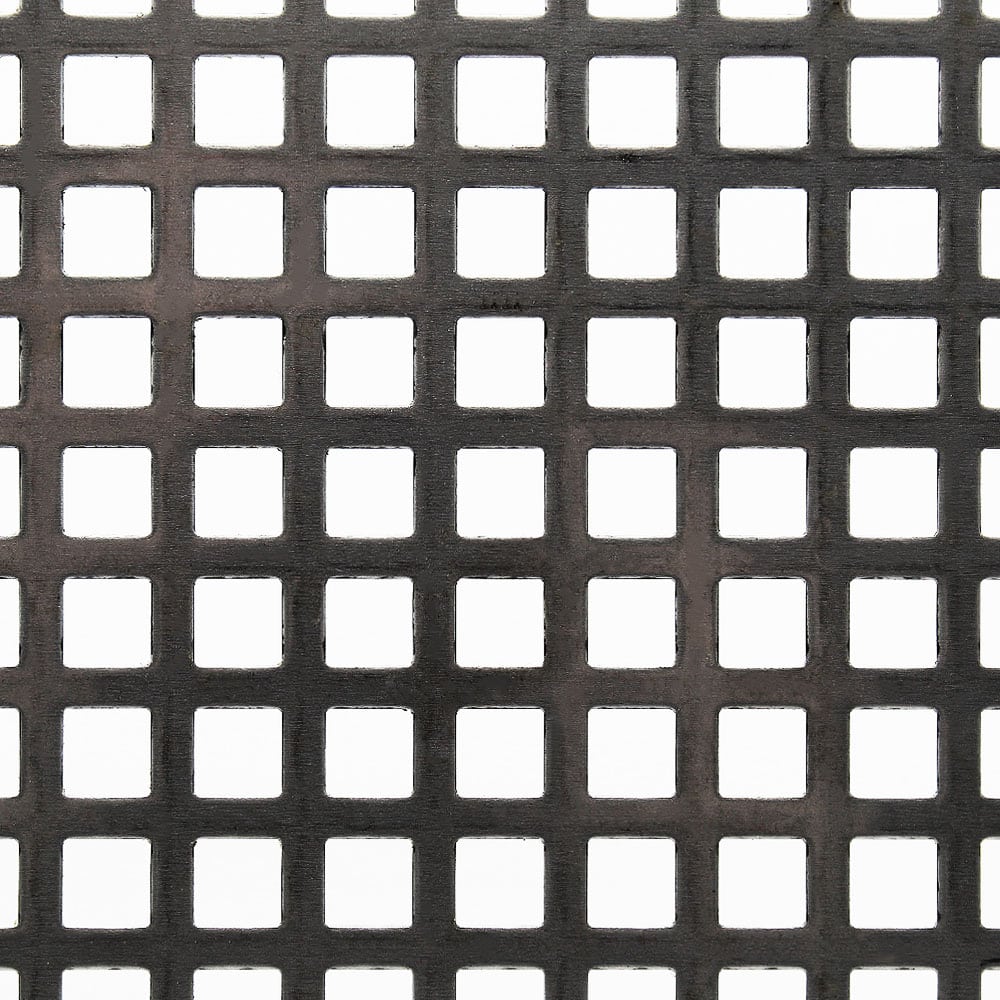

The standard options that we have in stock are square and round hole perforations.

Here is a simple breakdown:

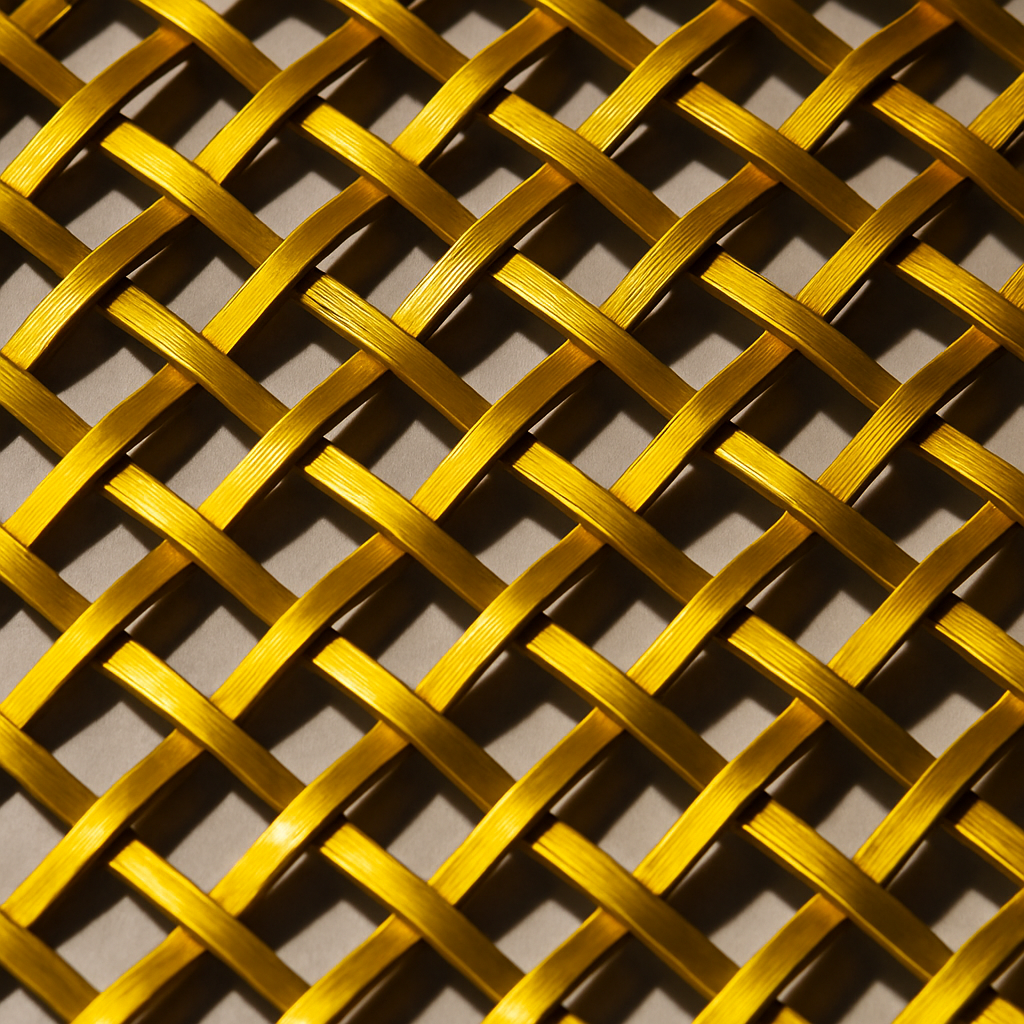

Square hole perforated metal mesh offers several advantages over other types of perforated metal mesh.

First, the square-shaped holes provide a clean and modern look that is aesthetically pleasing, making it a popular choice for architectural and design applications.

Second, the square shape of the holes allows for a higher open area, meaning there is more open space in the mesh for airflow, light, and sound to pass through. This makes square hole perforated metal mesh ideal for applications where ventilation, acoustic control, or light diffusion is necessary. We offer some square options with very high hole to pitch ratios.

Third, the square shape of the holes provides a more uniform distribution of perforations, resulting in a more even and consistent pattern of perforations across the sheet. This makes square hole perforated metal mesh easier to work with and more predictable in its performance. The square alignment of holes gives the stronger structure possible.

Round hole perforated metal mesh also offers several advantages that make it a popular choice for various applications.

The round shape of the holes allows for a high open area, which means there is ample space for airflow, light, and sound to pass through the mesh. A square hole gives the possibility of larger holes in relation to the pitch. Round holes tend to be in a pretty standard ratio between holes and metal gaps.

Round hole perforated metal is more common than the other shapes. This means that there tends to be more of a range available.

Round hole perforated metal mesh has a high strength-to-weight ratio and can withstand harsh environmental conditions, making it a durable and long-lasting option for many applications.

In conclusion, stainless steel perforated metal sheet is a versatile, durable, and aesthetic material that offers various advantages over other materials.

Its perforations provide it with unique properties such as ventilation, light diffusion, and sound absorption, making it suitable for a wide range of applications.

Stainless perforated metal mesh is a perennial favourite from our unbeatable range of mesh options. This is because of its longevity and durability mostly.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.