Choosing the right filtration medium is crucial to achieving precise results in industrial processing and laboratory applications.

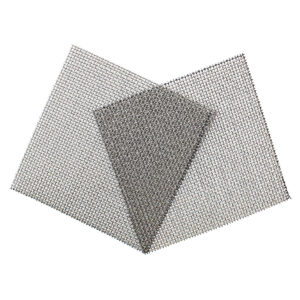

Stainless steel mesh filter discs are one of the most durable and efficient options available. Specifically, the 304 grade stainless steel mesh filter discs offer an ideal combination of strength, resistance to corrosion, and versatility, making them suitable for a wide range of filtration needs.

The Mesh Company offers a comprehensive range of 304 stainless steel mesh filter discs, meticulously designed to meet a wide range of application requirements. The range encompasses a variety of sizes and mesh counts, ensuring compatibility with virtually any filtration system. A filter disc can play a crucial role in any process, from industrial processing to intricate laboratory analysis.

Our range of immediate options are left over from our industrial processes.

This article intends to shed some light on what can be done with these discs in great depth. We hope that you find it to be of interest.

As always you can simply contact us if you require any further information on any of our mesh materials.

Let’s go…

Filter discs are made of 304 grade stainless steel, which is renowned for its corrosion resistance, temperature tolerance, and mechanical strength. Designed to withstand a wide array of chemical, physical, and environmental challenges, this austenitic stainless steel alloy contains approximately 18% chromium and 8% nickel. As a result of its resistance to oxidation and corrosion, filter discs can be exposed to a variety of chemicals and high temperatures without losing their integrity or performance. In addition to extending the lifespan of filtration systems, this resilience reduces maintenance costs.

Additionally, 304 grade stainless steel’s hygienic properties make it an ideal choice for applications requiring high levels of cleanliness, such as food and beverage processing, pharmaceutical manufacturing, and biomedical research. Its non-porous surface discourages bacterial growth and facilitates easy cleaning, ensuring that contaminants are not introduced during filtration.

In comparison to other materials used in filter discs, such as synthetic fibers or other metal alloys, 304 grade stainless steel consistently stands out for its superior durability, cleanliness, and versatility. With these attributes, it offers unrivaled reliability and consistency in filtration applications, making it not only a functional choice but a financially prudent one as well. In the following sections, we will discuss the extensive range of 304 stainless steel mesh filter discs offered by The Mesh Company, their applications, and how to select the right mesh count and size for your specific filtration needs.

The purpose of filtration is to remove particulate matter from liquids or gases across a wide range of industries. Efficacy of this process is largely determined by mesh size, measured in lines per inch (LPI), and wire diameter. Collectively, these dimensions determine the mesh aperture size, which in turn determines filtration capacity. Lower LPI values indicate larger apertures for coarser filtration, while higher LPI values facilitate ultra-fine filtration by featuring smaller apertures.

When tailoring filtration solutions, aperture size is crucial. For coarse filtration, such as removing large particulates from industrial wastewater, mesh counts may be in the lower range, allowing for rapid flow while capturing significant debris. The ultra-fine filtration of pharmaceuticals or precise laboratory analyses, on the other hand, requires higher mesh counts with minute apertures to capture microscopic particles.

Optimizing filtration performance requires selecting the right mesh count and wire diameter. For instance, a mesh with 120 LPI and 0.08mm wire diameter is well-suited for applications requiring a balance between strength and fine filtration. For applications requiring meticulous separation of fine particles, mesh counts of 325 LPI and wire diameters as fine as 0.035mm are ideal.

There are several distinct advantages to disc-shaped filters over other types, including a large surface area, ease of installation, and high flow efficiency. With their compact and flat design, disc filters offer an increased surface area for filtration without significantly increasing the footprint of the system. By using this design, fluids or gases are filtered thoroughly without unnecessary slowdowns or pressure drops.

Disc-shaped filters are also easy to install. As a result of their standardised shape, they can be easily integrated into various housing and equipment configurations, simplifying assembly and maintenance procedures. Disc filters are also adaptable and can be used in a variety of settings, including simple water purification systems and complex industrial processes requiring precise filtration.

A filter disc’s shape, size, and material all contribute to the overall efficiency and effectiveness of the filtration process. Disc filters offer robust filtration solutions adaptable to a wide range of applications thanks to their pragmatic design and compatibility with 304 grade stainless steel.

304 stainless steel mesh filter discs find application across a wide range of industries, each with its own filtration requirements. Particulate contaminants are separated from chemical mixtures using these discs, ensuring the purity of final products. They are critical in the production of wines, beers, and processed foods, where safety and clarity are paramount.

Pharmaceutical manufacturing presents another critical application, where the precision of filtration directly impacts drug purity and efficacy. Due to their high corrosion resistance and ability to withstand sterilisation processes, stainless steel mesh discs of 304 grade are indispensable. In addition to water treatment and air quality assessment, where removing pollutants and particulate matter is essential for health and compliance with regulatory requirements, these discs are also useful in environmental monitoring.

Case studies demonstrate the effectiveness of high-count mesh discs in pharmaceutical filtration in removing microscopic impurities, thereby safeguarding patient health. Low mesh counts facilitate the separation of larger particles in food production, ensuring beverage clarity and quality.

In order to select the right mesh filter disc, it is important to balance filtration efficiency with the physical and chemical demands of the application. Key considerations include:

It is advisable to consult filtration experts to determine the optimal mesh configuration for your project. Due to their extensive experience and technical expertise, they can provide insights into the most effective combinations of mesh count, wire diameter, and disc size.

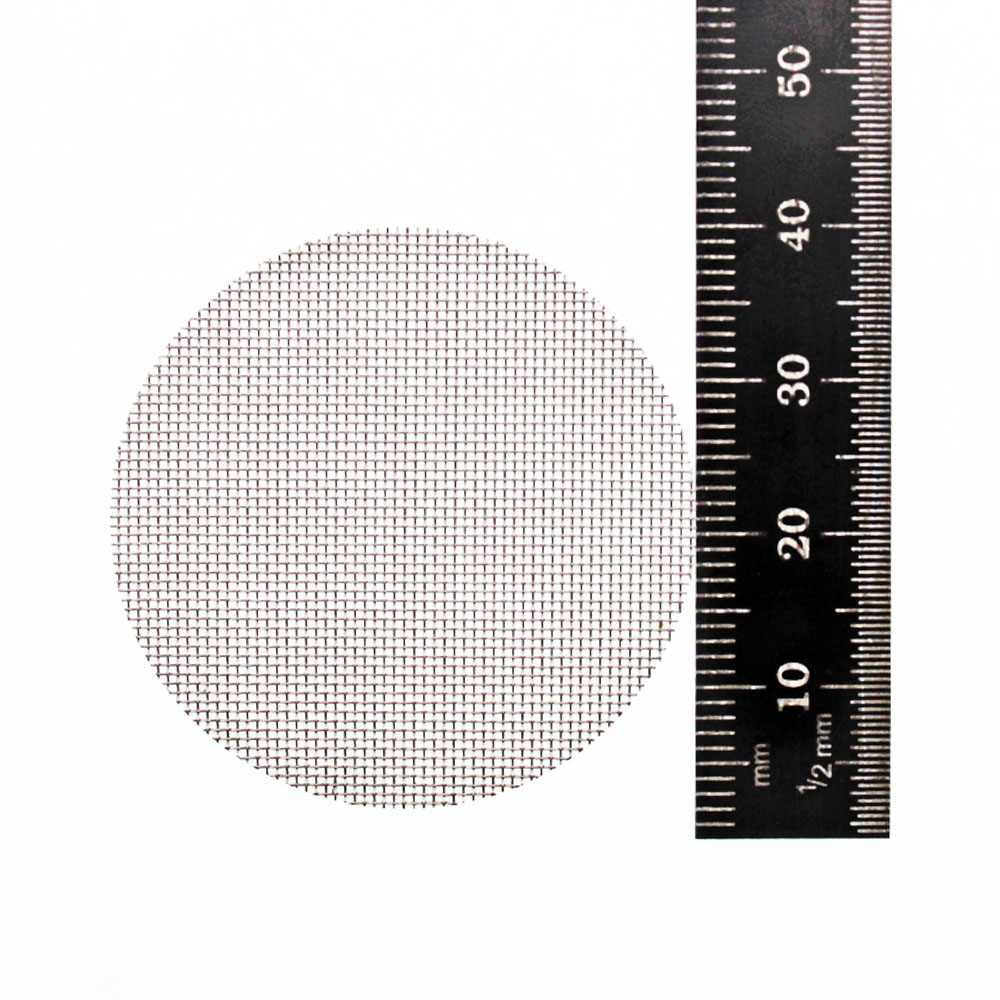

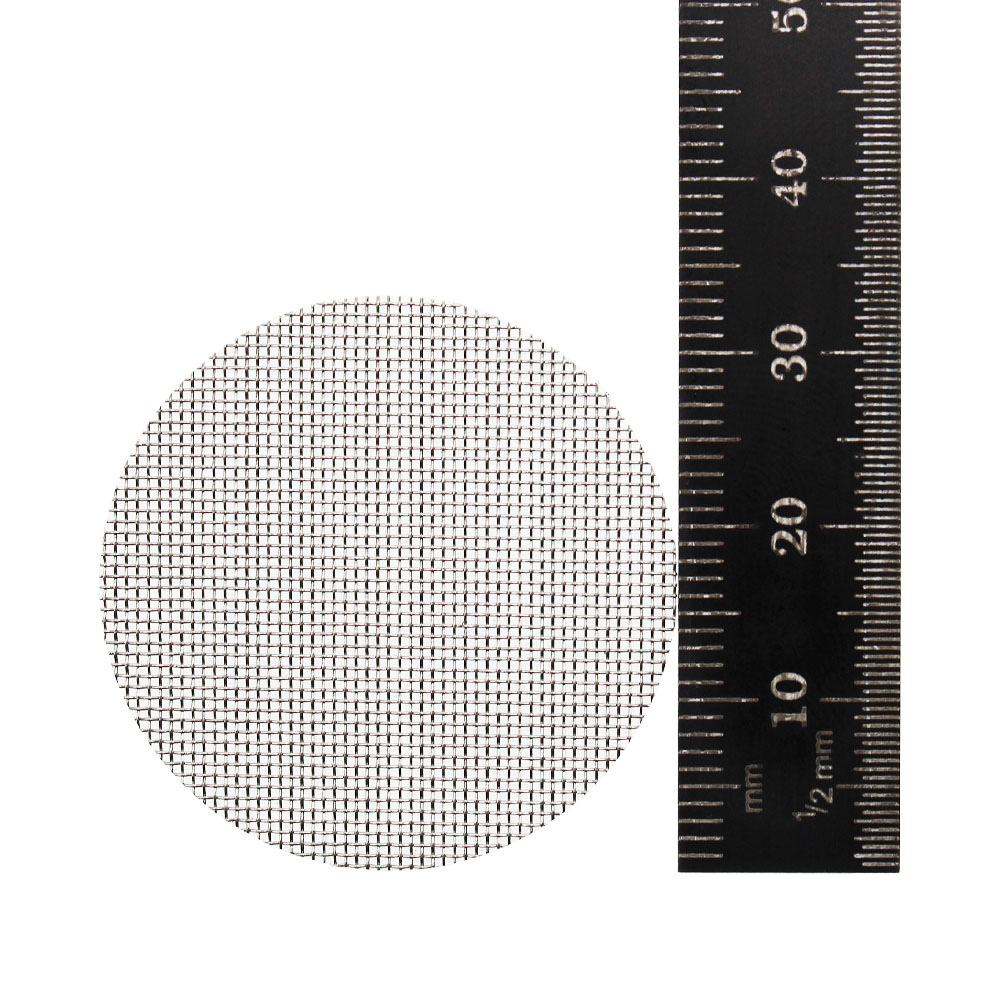

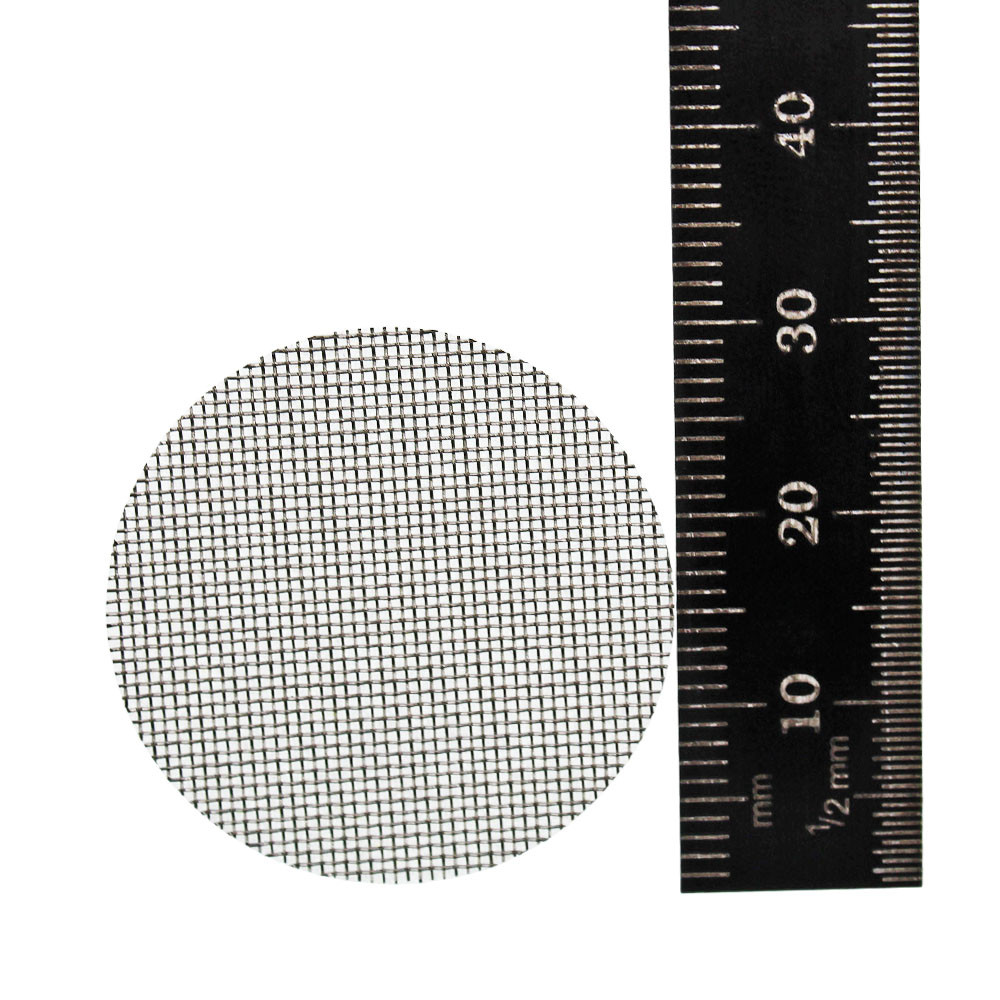

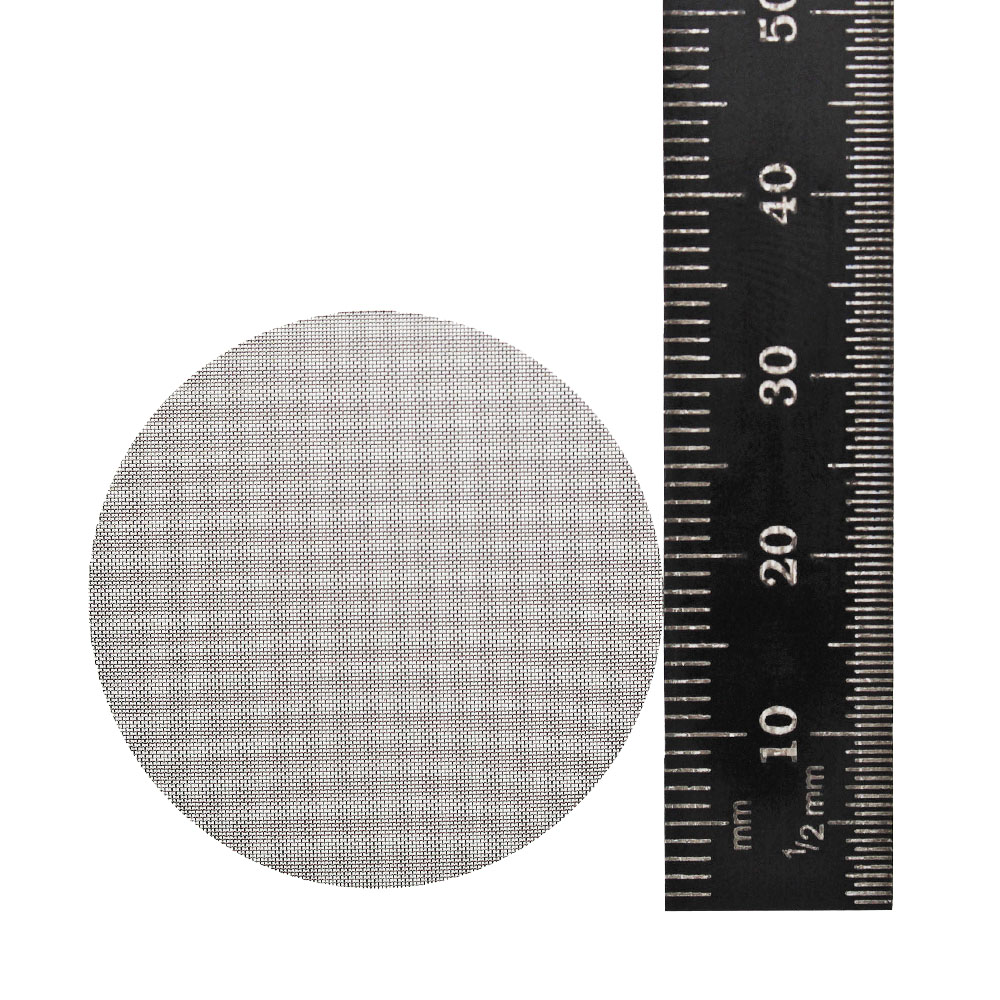

Here is an example of some of the options that we have available:

| Mesh Count | Wire Diameter (mm) | Disc Diameter (mm) | Description |

| 120 | 0.08 | 20 | High precision filtration |

| 200 | 0.05 | 20, 29.5 | Ultra-fine filtration |

| 80 | 0.14 | 36.83 | General industrial use |

| 40 | 0.25 | 29.5, 31, 32.5 | Coarse filtration, large particulates |

| 325 | 0.035 | 32.5, 33.5, 40 | Specialty applications requiring very fine filtration |

| 300 | 0.04 | 33.5, 78 | Advanced filtration needs |

| 100 | 0.1 | 40, 54, 33.5, 29.5 | Versatile, balanced filtration |

| 60 | 0.16 | 40, 54, 12.7 | Medium to fine filtration |

| 10 | 0.9 | 241.3 | Very coarse, structural applications |

A 304 grade stainless steel mesh filter disc plays a vital role in the filtration needs of various industries, offering a combination of durability, precision, and versatility that cannot be matched by any other material.

This filter disc ensures the purity and quality of your products, regardless of whether they are used for chemical processing, food and beverage production, pharmaceutical manufacturing, or environmental monitoring.

We invite you to explore our extensive selection of mesh filter discs at The Mesh Company. We guarantee that you will find the perfect solution for your filtration challenges, enhancing both your efficiency and the outcome of your operation.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to calculate open area % in mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions